Stefan Balatchev, Naftosense’s R&D coordinator, explains how its polymer absorption sensors are helping solve enviromental and operational challenges

Leaks in pipelines, storage tanks, and industrial systems pose serious risks, including hazardous spills, environmental contamination, and financial losses. Traditional leak detection methods, such as visual inspections, pressure monitoring, and infrared sensing, often have limitations in accuracy, responsiveness, and cost-effectiveness.

Polymer absorption sensors offer a cutting-edge, real-time solution for leak detection. These sensors are capable of detecting hydrocarbons and other chemicals with high sensitivity and reliability, making them invaluable for modern oil and gas operations.

Understanding Polymer Absorption Sensors

Polymer absorption sensors work by selectively absorbing specific molecules using engineered polymeric materials. These sensors utilise polymers designed to detect hydrocarbons, volatile

organic compounds (VOCs), and other substances relevant to the oil and gas industry. When the target molecules interact with the polymer, the sensor undergoes a measurable change, such as swelling, weight gain, or alteration in electrical or optical properties. These changes generate sensor signals, allowing for precise leak detection.

Working Principle

The functionality of polymer absorption sensors depends on three key elements:

- Selective polymer materials: The polymer must have a high affinity for the target chemical species.

- Absorption mechanism: The polymer absorbs the target compound, leading to physical changes such as expansion, viscosity alteration, or dielectric property modifications.

- Signal transmission: Changes in the polymer properties are converted into detectable signals through optical, electrical, or mechanical means. The most common sensing technique involves measuring variations in the material’s electrical properties, such as resistance or capacitance.

Applications of Polymer Absorption Sensors

Polymer absorption sensors are particularly valuable in detecting leaks in oil and gas infrastructure due to their high sensitivity, rapid response, and adaptability to various environments.

Pipelines serve as the critical arteries of the oil and gas transportation network, and their integrity is paramount to avoid severe economic and environmental damage. To safeguard against leaks, polymer absorption sensors have been effectively utilised along pipeline routes, including block valves and pig launchers, to provide continuous surveillance for hydrocarbon leaks. These sensors are sensitive enough to detect even the smallest of leaks, offering early warnings that empower operators to address potential issues swiftly, preventing them from escalating into significant hazards.

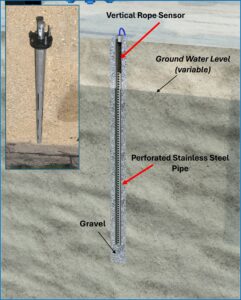

Similarly, storage tanks, which are susceptible to leaks caused by structural degradation, corrosion, or mechanical failures, are monitored for safety. By placing polymer absorption sensors below or around these tanks, it’s possible to detect vapour or liquid leaks early on, averting substantial spills. This technology is especially beneficial for monitoring hard- to-inspect tanks, such as underground storage tanks or those with floating roofs.

The offshore oil and gas industry, with its platforms and subsea pipelines, faces the unique challenge of operating in harsh marine environments where leak detection is both critical and difficult. Polymer-based sensors, which are designed to withstand extreme conditions, are deployed to monitor

these structures, capable of detecting oil spills in real time. Their durability and low maintenance requirements make them well-suited for the demanding conditions of deep-sea environments.

Refineries and chemical processing plants, which deal with a variety of hydrocarbons and hazardous materials, also rely on these sensors. Integrated into process monitoring systems, polymer absorption sensors can identify leaks in pipelines, valves, and storage tanks, providing immediate data that is crucial for preventing accidents and enhancing overall plant safety.

Applications for New Fuels

As the world shifts towards low-carbon fuels, ethanol and methanol have become popular as cleaner alternatives to traditional fossil fuels. Polymer absorption sensors have proven effective in detecting leaks of these alcohol-based fuels within storage and transportation systems, ensuring their safe management and mitigating the risk of environmental contamination. The technology is also capable of monitoring other biofuels, including biodiesel, bio-jet fuel (also known as SAF or BAF), and green gasoline.

The emerging field of liquid organic hydrogen carriers (LOHC) represents a novel approach to hydrogen storage and transportation. Ensuring that LOHCs are handled without leaks is crucial for maintaining system efficiency and safety. Polymer-based sensors excel in detecting LOHC leaks by pinpointing specific hydrocarbons and chemical changes, which allows for prompt corrective measures. Their integration into hydrogen-based energy systems is a step forward in enhancing the reliability and safety of sustainable energy solutions.

Advantages of Polymer Absorption Sensors

The adoption of polymer absorption sensors in the oil and gas industry offers numerous advantages over traditional leak detection techniques:

• High sensitivity and selectivity: These sensors can detect even low concentrations of hydrocarbons, making them ideal for early leak detection.

• Rapid response time: The absorption mechanism allows for fast detection of leaks, reducing response time and mitigating potential damage.

• Low maintenance and cost- effectiveness: Compared to complex electronic sensors, polymer sensors require minimal maintenance and have lower operational costs.

• Adaptability to harsh environments: Polymer-based sensors can withstand extreme temperatures, pressure variations, and corrosive conditions.

• Versatile for above- and below- grade applications: The same sensor can be used for both, including oil-on-water detection.

• Real-time monitoring and automation: These sensors can be integrated into IoT-based monitoring systems, allowing remote tracking and automated leak detection alerts.

Naftosense’s Advanced Leak Detection Technology #

Naftosense has developed a state-of-the- art patented hydrocarbon leak detection system that integrates advanced polymer absorption sensor technology with innovative design and analytical features. This combination ensures precise, real- time monitoring of critical infrastructure in the oil and gas industry.

Key features of Naftosense’s sensor technology includes double-jacketed sensor design. This dual-layer configuration ensures dependable performance for detecting target polar and non-polar fluids while withstanding extreme environmental conditions. Additionally, advanced analytical algorithms, based on extensive records from thousands of installed sensors, helps Naftosense employ AI-driven algorithms to minimise false alarms while maintaining high sensitivity to actual leaks.

Naftosense’s systems are designed with versatility in mind, supporting a variety of control methods and power sources such as AC/DC, solar power, and long- life internal batteries. This ensures that

continuous monitoring can be maintained across diverse operational environments. The system incorporates addressable sensor cables and robust sensing probes that are capable of detecting a broad spectrum of hydrocarbons and solvents, including refined products, crude oils, lubricants, ethanol, methanol, and various petrochemical compounds.

The construction of Naftosense’s leak detection systems is both robust and durable, built to function reliably within a wide temperature range of -55°C to +100°C. Their quality and longevity are underscored by a 10-year factory warranty, demonstrating a strong commitment to excellence. When it comes to monitoring, the systems offer comprehensive coverage and are equipped to provide real-time alerts. If the target fluid is detected, the system can trigger alarms, send notifications to users through remote monitoring, shut down equipment, or activate ventilation systems to promptly address and mitigate any risks.

Furthermore, Naftosense excels in adaptability, delivering customised solutions that meet the demands of challenging applications. The company provides industry-approved, long- term leak detection systems that integrate seamlessly with common communication protocols and feature location-based alarms, ensuring effective and reliable leak detection in even the most complex scenarios.

By integrating these unique features, Naftosense’s sensor technology offers a comprehensive and reliable solution for hydrocarbon and solvents leak detection, enhancing safety and environmental protection in industrial settings. Additionally, combining polymer absorption sensors with AI-

driven data analytics improves accuracy and predictive capabilities.

Conclusion

Polymer absorption sensors represent a transformative innovation in leak detection for the oil and gas industry. Their ability to provide real-time, high- sensitivity monitoring of hydrocarbons and low-carbon fuels makes them invaluable for enhancing safety, preventing environmental disasters, and optimising operational efficiency. With ongoing advancements in research and technology, these sensors will become even more essential for sustainable and secure energy production.