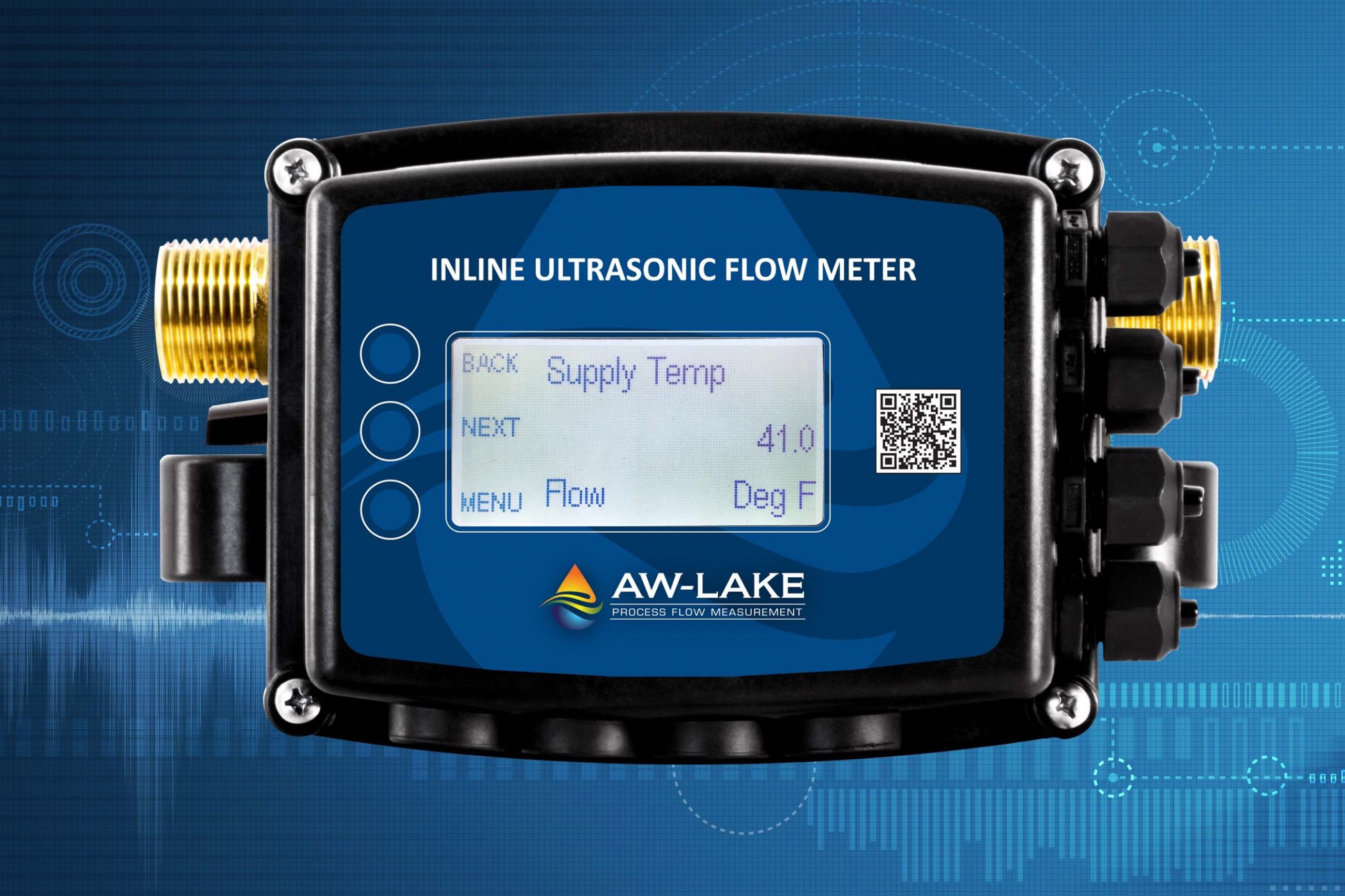

North American flow measurement technology firm AW-Lake has launched its new Water Inline (WIN) Ultrasonic Flow Meter for the flow measurement of cooling water, condensing water, and water/glycol solutions.

The flow meter is designed for process cooling applications including industrial cooling circuits. It is highly accurate (+1.0% of reading over 25:1 turndown, 100:1 total turndown) over a wide flow range with minimal pressure drop. The design incorporates two wetted ultrasonic transducers that face each other directly in the flow tube, reducing wear associated with moving parts for long-term reliability and low maintenance costs. This also maximises signal strength. The innovative flow tube design simplifies installation in limited straight runs and ensures no obstruction in the flow path. The WIN Ultrasonic Flow Meter operates safely when temporarily submerged in water and holds an IP 67 (NEMA 6) rating.

An LCD display version comes with Modbus RTU communications as standard, providing an output of flow rate, volume total, run hours, alarms, and diagnostics. The display is detachable for remote mount installation up to 5’ (152 cm) from the sensor. The flow meter’s built-in data logger enables easy data access vis Modbus. Units without a display come with analogue and pulse outputs as standard, 24V AC/DC power, one pulse, and one analogue output.

The WIN Ultrasonic Flow Meter completes the AW-Lake family of flow meters for cooling circuits. The other meters are the TRG Standard Turbine Flow Meter for monitoring solvents and other viscosity fluids, the FlowStat Paddle Wheel Flow Meter for monitoring various fluids in applications such as chillers/cooling circuits and HVAC, and the Variable Area Flow Meter for monitoring pump performance and oil or water flows through cooling systems.