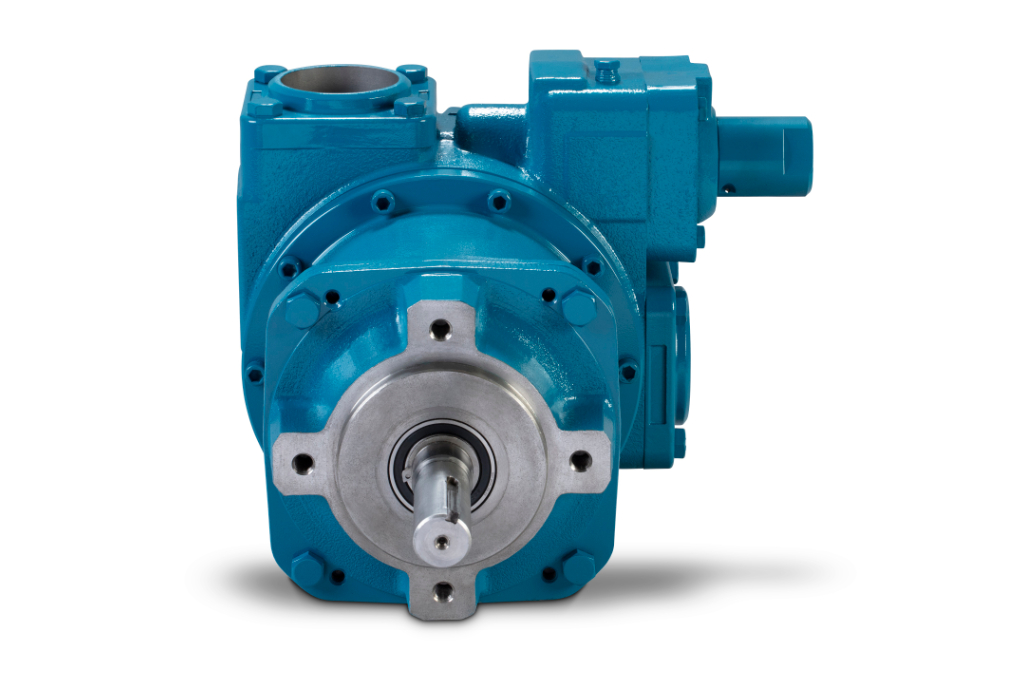

Global speciality pumps and compressor firm Blackmer has launched its new MAGNES series sliding vane magnetic drive pumps.

The pumps, which are positive displacement rotary vane pumps, can adapt to various problematic situations, including unexpected dry runs, pumping fluids with solids, handling of fluids with entrained vapours and poor inlet conditions, and inflexible pump operating ranges The company says that the pumps can also deliver technically superior handling of hazardous chemicals in severe-duty applications.

The MAGNES series pumps use seal-less magnetic drive technology and are suitable for difficult-to-seal, expensive, valuable, dangerous and hazardous liquids. They are leak-free, and as they use sliding vane technology, can offer various advantages including self-priming, line-stripping, product recovery, indefinite dry-run capability, solids handling, thin/thick viscosity flexibility, easy maintenance, low to zero NPSHr, 70–90% pump efficiencies, and full-curve operational flexibility.

The pumps are constructed from ductile iron and stainless steel with a non-metallic, proprietary composite containment shell. They are also available with a close-coupled drive design to allow east system setup without a time-consuming alignment process.

Currently, only a 3-inch model is available, but this will be followed in January 2021 by a 4-inch version.