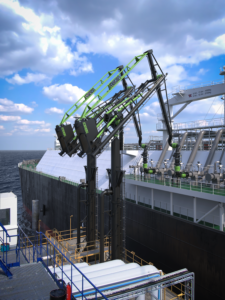

Discover how Isoil’s latest innovation is improving operational efficiency at the terminal Launching at StocExpo 2024 on 12 & 13 March at the Rotterdam Ahoy, Isoil’s VEGA T2 is the ultimate solution for automated terminal loading and unloading. Whether used within oil depots or transfer lines, the device is compatible with almost any type of flow meter. Enhanced Connectivity VEGA T2 is compatible with a range of communication lines, including serial lines, Ethernet, Bluetooth and WiFi. This allows the device to communicate directly with the control room, share delivery information and receive the instructions to operate from a […]

This post is only available to members. Please login below, or purchase Tank Storage Magazine Subscription – Print & Digital Subscription or Tank Storage Magazine Subscription – Digital Subscription to access this post.

log in

log in