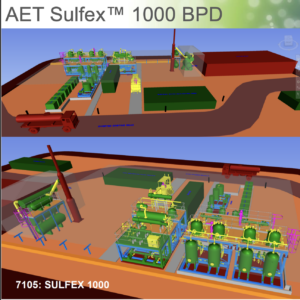

Alternative Environmental Technologies (AET) has announced that its design, procurement, assembly, and installation work of the initial SULFEX commercialisation project is near 70% completion.

The process is being installed at a liquid fuels pipeline terminal on the United States East Coast. Site work is planned to begin shortly.

The process is being installed at a liquid fuels pipeline terminal on the United States East Coast. Site work is planned to begin shortly.

The 1000 barrel per day (bpd) diesel desulfurisation plant design is on-schedule and expecting commissioning and startup to occur during 1Q 2024.

Soon after startup the plan is to expand capacity to 5000 bpd at that site then implement the process at several more terminals across the USA.

Barry Dallum, AET’s vice president of business development says: ‘The SULFEX process shows how removing complexity, along while significantly reducing safety hazards, as well as health and environmental hazards, can greatly reduce costs and project cycle times in accordance with LEAN design principles. Typically, a diesel fuel sulfur reduction project would take around twice as long than the speed at which this SULFEX design and installation process is occurring. We are thrilled with the initial results and look forward to numerous follow- on opportunities in the next several quarters.’

Stringent United States Environmental Protection Agency and global environmental regulations are demanding dramatic reductions in sulfur levels in fossil fuels to less than 15 parts per million (PPM) from several hundred PPM and heavy oils from several percent to less than 1%.

In comparison to the current, hydrodesulfurization (Hydrotreating or HDS), AET’s desulfurisation technology, has:

• Lower capital expenditure (CapEx)

• Lower operating expense (OpEx)

• Reduction in greenhouse gas emissions – methane and carbon dioxide

• Improved safety

AET’s Sulfex processes have been independently verified by the U.S. Department of Energy’s Argonne National Laboratory with mass and energy balances validated by 2 major EPC’s and has been beta tested in Thailand.

For additional information please visit:

https://www.alt-enviro-tech.com/

Or contact Barry Dallum at:

+1.918.805.0934

bdallum@alt-enviro-tech.com