MARINE OPERATIONS IN A DIGITAL WORLD

How the UAB-Online SaaS platform is optimising marine operations for liquid bulk handling for sea-going and inland vessels. Dutch-based liquid bulk handling specialist UAB-Online is sure that the time and cost savings its software brings to North European trades can be replicated on the international high seas. In fact, the firm is gearing itself up to dominate this market. These may be tough goals to achieve, but discussions to expand the UAB-Online SaaS (Software-as-a-Service) application system to the sector have already started; with interested parties in the ports of Houston, US and Singapore. UAB-Online’s digitised platform is recognised as the […]

DATA-DRIVEN DECISIONS

Cameron LNG enhances process performance via Hint’s automated information management system. Automation is on the minds of most companies striving for more efficient operations, cutting the cost to run and maintaining business-critical process equipment. Automated information management system fine-tuning and client-software provider collaboration in response to ever-changing needs can meet multiple challenges, as Cameron LNG found out. CAMERON LNG’S PROJECT Cameron LNG recently installed new fiscal metering for gas chromatographs (GCs), which are analytical instruments that measure the content of various components in a sample of liquified natural gas (LNG). These metered instruments, used in the LNG separation and analysis […]

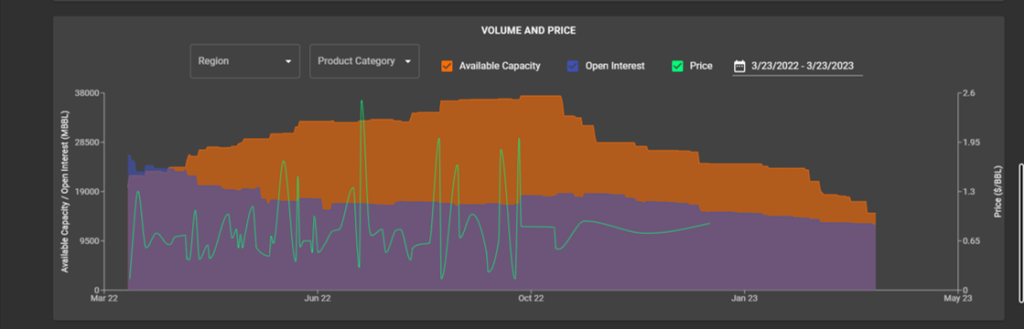

ESTABLISHING A DIGITAL MARKETPLACE FOR STORAGE OPPORTUNITIES

The Tank Tiger tells Tank Storage Magazine why digitalisation in the sector is so important and how it can be implemented to make processes seamless. In the days before Airbnb, there was no way to communicate to each interested party the myriad of living spaces with spare capacity, in real time. However, with the advent of online marketplaces, each seller could update their portfolio in real time, and buyers could efficiently query through a large database, across multiple variables, to find what they need. As a result, Airbnb not only made the hospitality industry more efficient, but also expanded it […]

DIGITALLY CONNECTED SUPPLY CHAINS & TERMINAL AUTOMATION

Sam Reid CEO of Dearman Systems, discusses how the digitalisation of terminals and the wider supply chain is impacting operations. Terminal automation software has evolved since its inception in the 1980s. Over the decades, the software has increasingly been used to streamline loading operations, simplify inventory management, enhance security, and automate reporting. Generally, bulk liquid storage operators know that it is worthwhile to automate their terminals, but the level of automation can vary drastically. Some companies choose to install state-of-the-art field instrumentation and connect everything together in an automation system. Others choose to maintain some manual reporting and operational processes. […]

FIT FOR THE FUTURE

Bulk liquid storage provider TanQuid digitalises its Duisburg terminal with technology from downstream IT specialist Implico. In March 2022, the long- running innovation partners in the downstream sector, TanQuid and Implico, were pleased to announce the completion of a visionary digitalisation project. After intensive planning and implementation work, all processes at the Duisburg, Germany, tank terminal now run with the future-ready terminal management system (TMS) OpenTAS TMS 6.0. In addition, the team uses specialised cloud services from the innovative Supply Chain United (SCU) portfolio. The all-embracing software solution is designed to match the location’s unique requirements. It marks the logical […]

INCREASING EFFICIENCY, IMPROVING SERVICE AND REDUCING COSTS WITH AI

The experts at Supplai tell Tank Storage Magazine how the company is making artificial intelligence accessible to the tank storage industry. Supplai is an artificial intelligence (AI) software developer. The company was founded in May 2020 by CEO, Koen de Jong and CTO, Casper van Lit. Supplai implements AI algorithms that make processes more efficient and effective. It is forging ahead with tailor-made AI solutions, and de Jong’s background means he understands the particular challenges of the tank storage market. AI THAT DELIVERS VALUE ‘Supplai’s approach is to get to know the customer and how they work, understand their problems […]

DESIGNING IN SECURITY

Safwan Akram, MSS director at Help AG explains how Saudi Arabia is supporting key infrastructure in cybersecurity. With many terminals becoming increasingly digital, it opens doors for cyber-attacks. When talking about critical infrastructure such as tank storage terminals, any extraction of data or limitations of functionality can have a devastating impact on both a terminal operator’s reputation and finances. Incapacitating a terminal can also wreak havoc on global supply chains. This could push prices up even more, impacting local and global markets. Hackers targeting terminals are not amateurs – they are typically highly organised and professional groups that work systematically […]

RESILIENCE, SECURITY AND BUSINESS CONTINUITY

Holger Berens, chairman of the Board of the German Association for Critical Infrastructure Protection discusses holistic approaches to business security. The recent acts of sabotage on the Baltic Sea pipelines have shown that, in today’s disruptive times, the focus cannot only be on security against cyberattacks. In order to ensure adequate security, attacks from the air (e.g. drones), on land (e.g. overcoming perimeter protection) and from the water (e.g. remotely operated submarines) must be included in the risk and business impact analysis. Of course, cyber threats cannot be ignored, either. The question has to be how a holistic security system […]

EVERYTHING YOU NEED TO KNOW ABOUT ESOS PHASE THREE

Dan Ellis, head of sustainability at Adler and Allan, discusses how to ready your operations for the government’s new regulations. The government’s Energy Savings Opportunity Scheme (ESOS) aims to boost the energy efficiency of UK businesses. It’s a mandatory programme that applies to large UK companies with a specified turnover and headcount. As part of ESOS, qualifying businesses must track and report energy usage across their buildings, processes, and transport. They’re also encouraged to find cost- effective ways to cut consumption. The scheme runs in four-year phases. Adler and Allan is currently in phase three, and the countdown to compliance […]

ADAPTING TO CHANGING NEEDS

Simon White, Stanlow Terminals’ lead engineer, looks at how the terminals industry is adapting to growing climate pressures and how Stanlow itself is supporting the drive to net zero. As the UK moves to embrace the next steps in its net zero campaign, the use of traditional fuels is set to decline, while sustainable alternatives will play a growing role. The pace of change is accelerating as 2030 comes ever closer and the UK strives to hit emissions targets by 2050. Information recently published by the Hague Centre for Strategic Studies (HCSS) covering tank storage in global supply chains has […]

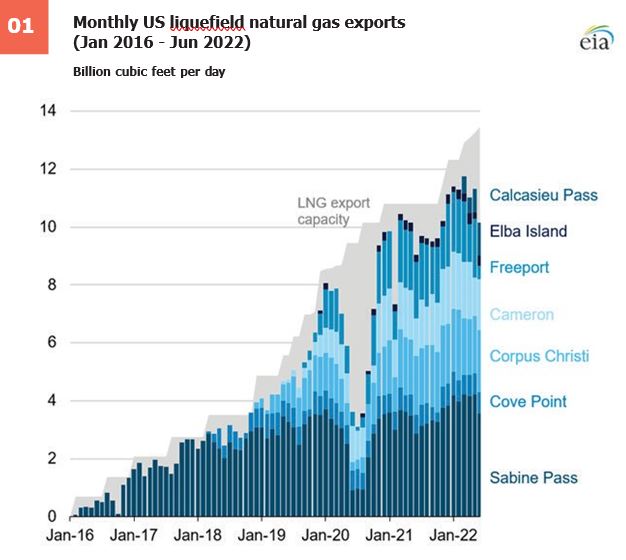

CRUCIAL & SUSTAINED ROLE FOR LNG IN ASIA’S SUPPLY

DNV analyses how the demand for LNG in Asia is expected to change. Energy demand is expected to continue rising across Asia, with a predicted peak in the early 2030s; approximately 20% higher than 2020 levels, according to DNV’s Energy Transition Outlook. Renewable sources are expected to meet a majority of the growth forecast. However, the medium-term growth potential of greener options in Asian markets is limited by challenges in integrating them with existing electrical infrastructure, all while ensuring reliable, secure, and dispatchable power. This means that the requirement for natural gas, the lowest carbon fossil fuel, will also grow […]

STOCKPILING, ENERGY SECURITY AND THE SINGLE MARKET

FETSA’s executive director, Ravi Bhatiani, tells Tank Storage Magazine about the proposals for a Single Market Emergency Instrument. A more volatile world leads to greater economic planning for worst case scenarios. In September, the European Commission proposed a Single Market Emergency Instrument. While this was partly triggered by the war in Ukraine, it was mostly prompted by the lack of stockpiles of critical supplies at the start of the pandemic and the semiconductor shortage. In summary, the Single Market Emergency Instrument establishes a framework of measures to anticipate, prepare for and respond to impacts of crises on the single market. […]

EUROPE’S AMBITIOUS NEW AMMONIA TERMINAL

Tank Storage Magazine speaks to ACE Terminal’s project director, Egbert Vrijen, to find out how this cross-company collaboration is facilitating the import of ammonia as a hydrogen carrier into northwest Europe. In the port of Rotterdam, three strategic partners, Gasunie, HES International and Vopak, have joined forces to develop an import terminal for ammonia as a hydrogen carrier. By working together, the group aims to use existing Gasunie pipeline infrastructure at the port, combined with Vopak’s tank storage expertise and HES International’s terminal experience. ACE Terminal is planned to be operational in 2026. ‘The planned terminal is strategically located with […]

ABU DHABI’S FORWARD-THINKING PETROCHEMICAL TERMINAL

Arabian Chemical Terminals Abu Dhabi’s commercial manager Mike Cromack tells Tank Storage Magazine what it means to be the region’s first independent liquid petrochemical facility. Founded in 1985, Arabian Chemical Terminals (ACT) has grown and expanded its expertise to become a key service provider in the breakbulk and general supply chain segments in the GCC region. With no existing commercial tank terminal in Abu Dhabi, ACT is developing a new site there for liquids and gases: the Arabian Chemical Terminal Abu Dhabi (ACTAD). The two- stage project at Khalifa Port will primarily serve KIZAD (Khalifa Industrial Zone Abu Dhabi), ZonesCorp […]

2022’S RISING STAR

We spoke to the winner of the Tank Storage Rising Star Award, Caitlin Geisinger, about her background and career. The Tank Storage Global Award for Rising Star is presented to ‘the person who is already paramount to the success of their company and who has the potential to become a key contributor to the future development of the tank storage industry.’ In 2022, Caitlin Geisinger was voted by the industry as the Gold Award winner. Geisinger is a business development manager, oil, gas and chemical, at US construction engineering company Burns & McDonnell. It’s fair to say that she was […]

TANK HEATING DESIGNED FOR A GREEN FUTURE

Enerquip’s custom engineered tank heating equipment is ideally suited for biofuels and bio-based feedstocks, explains Ron Herman. In 2008, Europe introduced laws requiring vehicle fuel suppliers to blend 5% biofuels into fuels, and in 2021 increased this to 10%. In the US, more and more states are now also mandating biofuel blending. This has led to an increase in demand for biofuels, and increased demand for equipment to handle them. For oil and gas companies used to handling self-lubricating, largely non-corrosive petroleum-based hydrocarbons, the storage and handling of biofuels and feedstocks generates new challenges. Such companies need to change infrastructure, […]

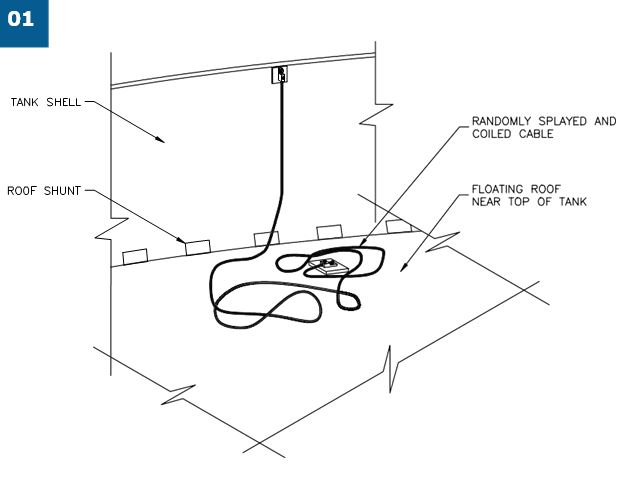

LIGHTNING FIRES, FRTS AND BYPASS CONDUCTORS

Joseph Lanzoni, VP of Sales Engineering for Lightning Eliminators & Consultants reveals how to avoid costly storage tank fires. Fires involving petroleum storage tanks are not uncommon. According to Henry Persson and Anders Lönnermark’s review of petroleum storage tank fires (1951-2003), the number of tank fires reported in the worldwide media is in the range of 15 to 20 fires per year. A petroleum industry-sponsored study concluded that lightning is the most common source of ignition, with about a third of all tank fires attributed to this. Floating roof tanks (FRTs) are especially vulnerable to lightning. The most common source […]

USING ROBOTICS TO KEEP ABOVE-GROUND STORAGE TANKS IN SERVICE

Matthew Myers from Square Robot shares how new technology can keep tanks in service for longer. Everyone with an above-ground storage tank (AST) recognises the challenges associated with tank inspections. The traditional method of taking a tank out-of-service only to perform a magnetic flux leakage (MFL) inspection can be a major burden on facilities, operations, and the teams managing tanks. Venting, cleaning, and blasting the bottom floor, just for an inspection, can leave a tank out of service (OOS) for months while costing hundreds of thousands of dollars in lost opportunity. What if there was a better way? A way […]

A TANK INSPECTION, REPAIR, MODIFICATION, AND TESTING OVERVIEW

Joe Mentzer from the Steel Tank Institute/Steel Plate Fabricators Association runs through the basics for field-erected storage tanks. Petroleum Institute’s (API) Tank Inspection Repair, Alteration, and Reconstruction standard, API 653, was first published in 1991 and was a consensus standard created through input from tank fabricators, users, regulators, and others involved in the storage tank industry. API 653 addresses the tank shell, foundation, roof, and appurtenances, and is used to identify degradation of a storage tank due to use and exposure to the environment. The standard provides a mechanism to inspect tanks built to API tank construction standards and a […]

THINGS I WISH I KNEW BEFORE I BUILT MY TANK

Jim Viale from Fisher Tank explains the basics. There are many things to consider when building tanks, but one of the most important considerations when planning a storage tank project is determining who needs to be involved. All stakeholders should have a voice in the process. Purchasing, operations, engineering, and a trusted contractor should all be involved so that no one is operating in a vacuum. A team approach, with both internal and external partnerships, and an investment of time and effort up front will save tank owners time and money both on the front end and on the back […]

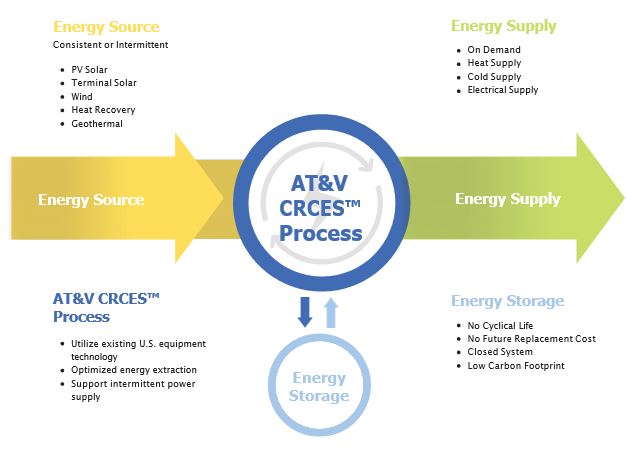

TOMORROW’S BATTERY TODAY

W.T. Cutts, director at AT&V reveals how the company’s cutting edge technology could solve battery storage issues in the industry. The global movement towards clean energy is a complex issue. Finding an affordable solution while balancing environment concerns, human rights, and the current energy enterprise, combined with the involvement of multiple governments, seems impossible. Yet the answer will present itself; one idea, one technology, and one solution at a time. One problem most people agree on is the battery of today does not work for larger storage requirements. Whether you are referring to performance, cost, carbon footprint, or negative impacts […]

EXTENDING TANK LIFESPANS USING INSERTED LINERS

Storage tank specialist John Cornell looks at the need for a change in approach to the use of bolted tanks and tank liners. The subject of tank inspections has been an on-going since the Great Molasses Flood in Boston, Massachusetts, US. On 15 January 1919, a storage tank owned by the Purity Distilling Company, filled with 2.3 million US gallons (8,700 m3) of molasses weighing about 12,000 tonnes, burst. The resulting wave of molasses moved through the surrounding streets at an estimated speed of 35 mph (56 km/h), killing 21 people, untold numbers of horses, dogs and other animals, and […]

OLDEST WAR AND NEWEST SOLUTION

Innovative Surface Prep reveals the secret to a long-lasting storage tank. The war has gone on for nearly 4000 years, and is still a constant battle to this day. It happens every day and most people pass right by without even noticing. This is not a war you will hear about on the news or learn about in history books, but it is a fight happening across the world. It’s the fight against corrosion – one that specialist in safe, cutting-edge, eco-friendly surface prep solutions, Innovative Surface Prep (ISP) is taking head on. The mitigation and prevention of corrosion is […]

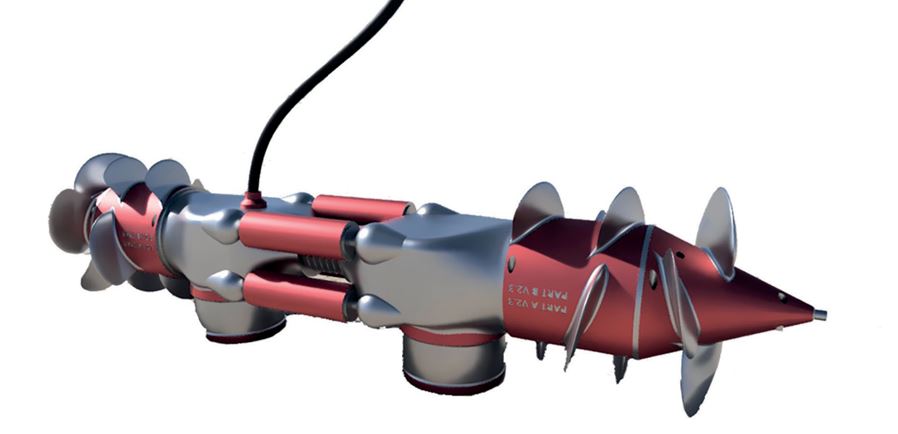

NEEDING A HERO

Joel Poe from Applied Impact Robotics discusses the founding of the company and what it can offer the tank storage industry. Applied Impact Robotics (AIR) was formed after winning the HeroX competition in November 2019, spearheaded by Malaysian oil major Petronas. Petronas was seeking a solution to close a critical gap within their storage tank inspection process and partnered with Chrysalix Venture Capital to create a contest to source and fund solutions with a prize of US$250,000 (€223,000) for development. In the 12 months following the initial award, AIR validated the core concepts of the design and key metrics to […]

TANK CLEANING EMBRACES SUSTAINABILITY

Cristin Johnson of USA DeBusk explains the new priorities of aboveground storage tank cleaning in the ESG era. In the past, aboveground storage tank cleaning projects were planned and executed with priorities focused predominantly on speed and cost. As long as safety and regulatory compliance standards were satisfied, the key performance indicators (KPIs) focused on metrics such as barrels of material removed and total time on site for the tank cleaning crew. With the increasing importance of environmental, social, and governance (ESG) factors, KPIs for turnaround time and price now share the spotlight with factors such as waste and carbon […]

RISE AND FALL

Paul Wiseman finds that Russia, COVID, inflation, and the strong US dollar are all driving the oil situation in North America. Early in the northern hemisphere summer of 2022, prices for West Texas Intermediate (the US benchmark) as well as Brent Crude (the European benchmark) dropped from previous highs due to concerns about China’s zero COVID policy and demand destruction in the US due to historically high pump prices. In July, US President Joe Biden met with Saudi Arabia’s Crown Prince Mohammed bin Salman. The stated reason was for a ‘reset’ and to ask one of the world’s biggest exporters […]

WAITING WITH BATED BREATH

ILTA explains what new technologies and procedures might improve terminal operations, and where regulations could be overzealous. The International Liquid Terminals Association (ILTA) and its member companies are dedicated to providing safe, sustainable, efficient, and reliable storage and logistics services for bulk liquids. In July 2021, the board of directors adopted the organisation’s first Environmental, Social, and Governance (ESG) principles. One of these principles affirms the industry’s commitment to continually reviewing new technologies and procedures that might improve emissions monitoring and yield emissions reductions. ILTA has put this pledge into action by engaging with the U.S. Environmental Protection Agency (EPA) […]

NEW PLAYER CHANGING THE GAME

Willow Glen Terminal speaks to Tank Storage Magazine about the growth of this young facility, and how they’re paving the way for renewable diesel and sustainable aviation fuel. Located on the site of a former gas-fired power station, Willow Glen Terminal (WGT) is a multi-modal logistics hub located in St. Gabriel, Louisiana, on the Lower Mississippi River. The power station was decommissioned in 2016, and WGT was formed in August 2020 by Zydeco Holdings (a Yorktown Energy Partners portfolio company) and Willow Glen Ventures to upcycle the former power station. The terminal formally opened earlier this year and features a […]

DOING THINGS DIFFERENTLY

Jay Reynolds and Ellen Ruhotas tell Tank Storage Magazine how Zenith is serving customers and facing the energy transition head-on. In 2014, terminal industry veteran Jeff Armstrong decided to set up a new midstream company, having left Kinder Morgan, where he was president, in 2013. The new company, he decided, needed to be smaller, more aggressive, more creative, more responsive, and more customer-focussed, than the companies already existing. With US$600 million (€590.2 million) in backing from private equity firm Warburg Pincus and US$100 million from co- investors, friends and family, Zenith Energy was born. Initially, the company sought opportunities in […]

HANDLING THE PRESSURE

Tank Storage Magazine talks to engineering specialist Transtech Energy about the challenges involved with building Vopak Moda Houston’s bullet tanks. As part of the Vopak Moda Houston project, EPC contractor Transtech Energy, which has over 30 years of experience in the design and construction of liquefied gas terminals and transloading facilities, was tasked with fabrication of the facility’s five pressurised 120,000 gallon bullet tanks. These tanks have a total storage capacity of 14,285 barrels for products such as propane or butane or other liquefied hydrocarbon gasses. ‘Typically bullet style tanks are built for aboveground installations, Mark Wenik, market director for […]

IN IT FOR THE LONG-HAUL

Jon Ackerman from Vopak Moda Houston tells Tank Storage Magazine about the first greenfield terminal in the Port of Houston in more than a decade. In December 2021, Vopak Moda Houston, a terminal in the Port of Houston, US, announced that it was fully operational. But this was not any old terminal. Vopak Moda Houston was the first greenfield terminal developed in the Port for more than ten years, built to handle anhydrous ammonia and speciality pressurised gases. The terminal is operated as a joint venture, set up in 2016 between Vopak and Moda Midstream. Moda Midstream was at the […]

PART OF THE SOLUTION

The 2022 conference of the Federation of European Tank Storage Associations (FETSA) was held in Brussels, Belgium. The focus for this year was very much on the future of the industry and how it will be able to adapt for the energy transition. It included interesting talks, lively panel discussions and even an interactive session with a smartphone app. FETSA chair Ulfert Cornelius welcomed attendees, noting that the last in-person meeting was in Tarragona in Spain in 2019, and that being back face-to-face would strengthen the networks. The tank storage sector is facing a number of challenges relating to the […]