PLAN WISELY, MANAGE YOUR RISK

Find out the benefits of risk-based inspection for API RP 581 and EEMUA 159 CHALLENGING times strongly drive the need to optimise existing procedures and systems while minimising business risks with day-to-day operations. When talking about tank integrity management, we deal with the challenge of balancing efforts and benefits while complying with safety regulations and standards requirements, bearing out the need of keeping tank full capacity and many times with the unavailability to timely carry out inspection and repairs. Risk-based inspection used as part of tank integrity management systems allows the integration of engineering and management processes in a systematic […]

TECAM: 15 YEARS OF GROWTH

The 2020 Tank Storage Magazine Environmental Performance Award winner looks back IN THE midst of the pandemic we are all living through, advanced environmental technology solutions company Tecam is celebrating 15 years in business. In August 2005 Borja Maestro founded Tecam Soluciones Medioambientales in Barcelona, Spain, as an environmental technology distribution company. That small start-up soon evolved to become Tecam Group, which began manufacturing environmental technology to eliminate polluting emissions from the industry. The path to now was not always easy. Bernat Sala (today’s Tecam CEO) joined the company in 2007 as sales director and shareholder to lead the company’s […]

PEERLESS GAS FLARING

Michele Nazzaro and Harold Kempinga from Aereon Europe discuss the Aereon CEB, the EU-certified best available technology for gas flaring operations MANAGING vapour recovery and the containment of volatile organic compound (VOC) emissions is a must. Not only are atmospheric emissions regulated by increasingly stringent legislation, but many companies have a growing culture and commitment for a cleaner planet. Vapours containing potential VOCs are generated from various sources, such ascrude oil transfer into storage tanks and road tankers, pipelines and vessels to be isolated and purged for maintenance, gas well testing operations, and many others. Scrubbers, carbon bed adsorption and […]

SINGLE-FLOW TWIN SCREW PUMPS FOR FLEXIBILITY AND EFFICIENCY

VPS single-flow twin screw pumps can adapt to a variety of flow media with low operating costs A TECHNOLOGICAL change is emerging in tank farm and chemical applications. Single-flow twin screw pumps have started to replace conventional positive displacement pump technologies at flow rates up to 500 m3 per hour. This is as a result of an increasing demand in flexibility, the permanent optimisation of operating costs and the required efficiency of rotating equipment to remain competitive. Tanks store a wide variety of products such as gasoline, heavy oils and various chemicals. Operating pumps in particular must have good suction […]

WSG’S GAS LEAK DETECTION AND REPAIR SERVICES

An innovative method using the world’s most sensitive optical gas imagery cameras IN ADDITION to their current support services to storage tank operators, which includes infrastructure projects, maintenance and UHP tank cleaning services, WSG are further growing their offering as a leak detection and repair specialist (LDAR) with the addition of WSG Enviro to the WSG Group. WSG’s aim was to make regular maintenance or maintenance during outages and shutdowns seamless, efficient and productive with minimum downtime required. WSG already had an extensive track record as a leak detection and repair specialist, supplying services from the existing core business lines […]

THE GREAT FOAM DILEMMA

A guide to choosing the most suitable foam for your fire protection needs IN 1902 Russian chemist and engineer Aleksander Loran developed and patented the first fire suppression foam for extinguishing flammable liquid fires, by physically mixing two powders and water. Many innovations to fire-fighting foam have since been developed, including Aerofoam (Percy Lavon Julian, 1942), high-expansion foam (Herbert Eisner, 1956), fluoroprotein foam (National Foam, 1965), aqueous form filming foam, AFFF (US Navy, 1966), alcohol resistant aqueous form filming foam, AR-AFFF (National Foam, 1973), and synthetic fluorine-free foam, SF3 (3M – 2002). All foam concentrates mentioned with the exception of […]

FIGHTING FIRE WITH ROBOTS

Meet the Netherlands’ remote controlled fire-fighting robot: the Inferno Beater HOLLAND Holland Special Pumps (HSP) is the only firefighting robot manufacturer in the Netherlands. Last year the company launched the Inferno Beater, a remotely-operated fire extinguisher robot, which can be used in tank farms, as well as other applications such as houses, industrial buildings and parking garages. The Inferno Beater contains a camera, so can be controlled even when the operator is out of sight, allowing the machine really close access to the fire. It can be connected to almost any type of water supply, such as hydrants, fire trucks […]

SAFETY IS AT THE HEART OF OUR OPERATION

If you are committed to enhancing safety and productivity in your operations and recognise that commissioning manned crews to clean tanks in hazardous environments is no longer an option, then Re-Gen Robotics has the answer to your tank cleaning requirements MANAGING Director, Fintan Duffy says that it’s time to move on from dangerous ‘man entry’ tank cleaning procedures that are outdated and time consuming. ‘Our state-of-the-art, explosion proof, Ex Zone 0 rated tank cleaning robots, do the jobs that are simply dangerous for people. “Not only do they operate in hazardous environments where humans can’t, but they can also take […]

ISGOTT: THE INDUSTRY GUIDE TO TANKER AND TERMINAL SAFETY

Rob Drysdale and Dave Wall from OCIMF run through the changes in the updated guide IN JUNE 2020, the International Chamber of Shipping (ICS) and The Oil Companies International Marine Forum (OCIMF), in conjunction with the International Association of Ports and Harbors (IAPH) published an updated edition of the International Safety Guide for Oil Tankers and Terminals (ISGOTT), a text which is widely regarded as the definitive reference guide for oil tankers and storage terminals. The primary purpose of ISGOTT is to provide operational advice to assist personnel directly involved in tanker and terminal operations. It makes recommendations for tanker […]

API’S LATEST EDITION OF OIL STORAGE STANDARD ADDRESSES OVERFILLING

Debra Phillips from the API runs through important updates to API Standard 2350 THE newly released 5th edition of API Standard 2350, Overfill Prevention for Storage Tanks in Petroleum Facilities, is a key update to a standard designed to prevent overfilling at oil storage facilities, which has become increasingly important to the industry as supply and demand trends are affected by the current pandemic. This new update supports improvement to operational safety, reliability, and environmental sustainability by supporting ongoing maintenance and risk management at oil storage facilities. Indeed, careful consideration was give to the benefits provided by overfill prevention relative […]

EMERGING INVESTMENT THEMES FOR TODAY’S STORAGE BUSINESSES

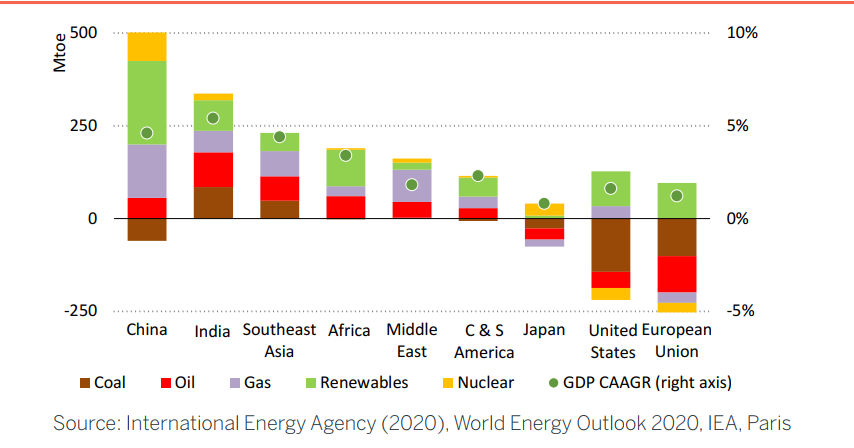

The investment environment in the light of IMO 2020, COVID and the acceleration towards energy transition THE CURRENT REALITY AND THE IEA PERSPECTIVE LIFE in 2020 is about COVID-19 and energy transition. We still do not have a clear answer for either. What is clear is that the world will decarbonise. Over time, fossil fuels will play a diminished role. The pace of change is still not clear. Without doubt there will be a repositioning in the tank storage sector and there will be localised casualties. Increasingly, investment is going to be driven by the requirements to be sustainable and […]

PLAYING A CRITICAL ROLE

A look at the importance of bulk liquid storage in the UK to the COVID-19 recovery and the energy transition. THE tank storage sector is essential to maintain our day-today life, providing a critical link in the transportation system for liquid products, from transport and heating fuels to chemicals and food-grade products. This year, as much as any other sector of the UK’s economy, bulk liquid storage has also felt the impact of COVID-19. During this challenging time, the industry and associated logistics continue to work tirelessly to keep critical infrastructure operating. Against a background of increased demand for petroleum […]

FUTURE-PROOFING A TERMINAL

Colin Horton from Oikos Storage in the UK speaks to Tank Storage Magazine about recent expansions and future plans. THE Oikos Storage terminal is situated on a 28 ha site about 65 km to the east of London, on Canvey Island in Essex, UK. It has more than 35 tanks with a total capacity of around 300,000 tonnes, and is the only independent terminal in the UK with access to the deep water navigable channel of the River Thames, and connected to the UK’s national fuel distribution pipeline networks. The terminal started operations in 1936 as a general purpose […]

AGILITY AND INNOVATION: HOW UM TERMINALS MEETS CUSTOMERS’ NEEDS

One of the UK’s leading bulk liquid storage companies has put in place a new strategic growth plan and unveiled a name change. UM Terminals managing director Bryan Davies explains. UNTIL quite recently, UM Terminals was known as UM Storage. But the Liverpool, UK-headquartered business has ambitious growth plans and felt that their old name did not do full justice to today’s business. Commenting on the company’s new name, managing director Bryan Davies says: ‘We felt that UM Terminals and the strapline ‘Bulk Liquid Solutions’ better described the services we offer. The range of services we provide our customers […]

THE PATH TO TANK OVERHAUL COST REDUCTION

Five essential pillars to decrease maintenance costs and increase tank availability EVEN in the best of times, those who lead tank storage facilities continue to search for practical, attainable solutions for maximising availability while keeping a firm control on maintenance costs. During the unusual circumstances of 2020, with storage capacity at a premium, tank operators are making unconventional and expensive decisions to boost their capacity. Returning tanks to service, deferring scheduled maintenance, and enacting temporary fixes, push costs higher and increase risk. But what if tank operators could deploy a proven solution to reduce both outage durations and cost? This […]

THE IMPORTANCE OF TRAINING FRONTLINE EMPLOYEES TO CONTROL SPILLS

A spill at a tank terminal is most likely to be discovered by an employee, and if they are properly trained, the spill response can be much faster TIME is a priceless commodity. It seems that this precious resource is being stretched further and further these days. Between natural disasters, labour shortages and worldwide pandemics, most people are finding the need to do more with less. One ill-timed, unplanned interruption can derail the workload for weeks – especially something like a petroleum spill from one of the outdoor storage tanks. Chances are good that a frontline worker is going to […]

USING 3D LASER TECHNOLOGY TO CAPTURE AND MANAGE ASSETS

A3D’s laser scanning technology offers an innovative way to prepare piping and instrumentation diagrams to support your operations A3D embarked on a journey eight ears ago using 3D laser scan data to design a range of applications specifically tailored to operators of process installations. Developed around a strong focus on clients’ operational needs. The company’s successful business model has resulted in the engineers developing a range of competitively priced, well-designed applications to assist clients. Whatever the size of your manufacturing, storage or refining facility, A3D’s engineered products enable operational efficiencies in the operation, maintenance, documentation and asset management of your […]

ABOVE ALL ELSE

The American Chemistry Council explains the background behind its Chemical Facility Safety Initiative SAFETY is an area close to the heart of any tank farm operator, but with multiple and changing assessment tools, standards, regulations, and guidelines, it can be a little perplexing. In 2019, following a series of high-profile chemical facility safety incidents in the Houston, Texas, region, the American Chemistry Council (ACC) convened an Ad Hoc Chemical Facility Safety Initiative Work Group in the US in an effort to offer clarity for chemical sites, including storage sites. Tara Henriksen is the managing director of the Responsible Care Initiative […]

3D SCANNING AND THE LIQUID TERMINAL CONTRACTOR

3D scanning equipment is a great tool, but it can do much more than just find corrosion or cracks 3D SCANNING manufacturers originally set their sights on the architecture, engineering and construction (AEC) industry, with an emphasis towards surveyors and construction engineers, for the manufacturing industry as a tool for use in reverse-engineering and prototyping, and archaeologists and historians as a useful documentation tool. As with most things digital and virtual reality-based, the technology continues to improve, the costs continue to go down, and an ever-growing number of users continues to find many new ways to leverage it. For anyone […]

SECURITY AND SAFETY REGULATIONS – WHAT TERMINAL OPERATORS NEED TO KNOW

Peter Lidiak, vice president of regulatory affairs, International Liquid Terminals Association (ILTA), looks at the latest US standards SECURITY and safety are two core values of bulk liquid terminal operators. As part of the critical infrastructure community, bulk liquid terminals must pay close attention to the safety of not only their workers and contractors but also the communities in which they operate. And because bulk liquid terminals serve as a hub for all modes of surface transportation, including pipelines, rail, ships, barges and trucks, they must be secure to safeguard continued, reliable operations and delivery of the products they handle, […]

DEMAND IN A DOWNWARD SPIRAL

The only things rising are bankruptcies and distressed asset sales in the US shale industry WE’VE never had a downturn like this, that affected shale on a global basis as much as this has,’ says Daniel Lippe, managing partner at Petral Consulting Company in Houston, Texas. ‘Never in 100 years has demand suddenly evaporated as it did in March of 2020.’ COVID-19 quarantines kept cars in driveways, planes in hangars and offices workers at home. With so many vehicles avoiding fuel stops, the oil and gas supply chain backed up. Lippe observed: ‘The distribution system is a self-regulating mechanism. You […]

THE NEW KID ON THE BLOCK

Why three former Oiltanking colleagues decided to launch Tivoli Midstream during a global pandemic. IN JULY 2020, three former Oiltanking colleagues and industry veterans announced that they had set up a new midstream, logistics and services company, Tivoli Midstream. Rance Fromme, Rick Adams and William Brod have over 70 years of experience between them, and decided the time was right to go it alone. ‘The idea of Tivoli started with casual conversations about trying to take advantage of opportunities in the market leveraging our vast experience in the midstream space. These conversations led to more conversations and before we knew […]

EXPLOITING CAVERNOUS CAPACITY

Easton Energy CEO Joel McComas tells Tank Storage Magazine about salt caverns and oil storage in Texas HYDROCARBON storage comes in all kinds of shapes and sizes – huge tanks, small tanks, in barrels, on ships, even in railway wagons and pipelines in recent months – but one of the biggest by capacity is in underground salt caverns. Underground salt caverns are created through a process called solution mining, where a well is drilled in a salt deposit and water pumped into the salt deposit to dissolve the salt and create brine, which is used in a variety of industrial […]

ACCELERATE THE FUTURE OF YOUR TERMINAL, TODAY

ON 27 May 2020, Tank Storage Magazine began a new venture – online professional seminars from industry experts. The first one, entitled ‘Accelerate the Future of Your Terminal, Today’, was given by John Colpo, Principal Analyst, Oil and Gas, at Honeywell. ‘We partnered with Tank Storage Magazine to help us maximise our reach with terminal operators around the globe – they covered all the bases on a promotional front, were flexible to our needs, and their industry knowledge all contributed to an easy partnership and successfully executed webinar,’ says Liliana M. Pereira, Global Customer Marketing at Honeywell Process Solutions. Colpo […]

A NEW SAFETY CONCEPT FOR PRESSURISED LNG STORAGE TANKS

LNG is the fastest-growing gas supply source in the world due to two crucial economic and environmental factors. On the one hand, LNG has a very attractive price and on the other hand – in terms of sustainability – clean burning gas produces significantly fewer emissions than oil and coal and has the lowest environmental impact amongst fossil fuels. LNG produces 25% less carbon when used in the power sector compared to fuel oil, 50% less carbon compared to coal, and 99% fewer particulates, 85% less nitrogen oxide (NOx) and 99% less sulphur oxide (SOx) than traditional fossil fuels as […]

TANK BOTTOM LIFE, RISK BASED INSPECTION AND CORROSION: PART 2

IN PART 1, we established a foundation for determining what a corrosion rate is and how it is used to establish tank internal inspection intervals. In this part we provide the methodology for using survival analysis (Sidebar 1) to properly quantify the useful tank bottom life which may then be applied to managing the inspection protocols of tank populations. [SIDEBAR 1: SURVIVAL ANALYSIS Survival analysis is a branch of statistics that is best suited to technically address rates of mortality and lifespan. This idea might be applied to: Cancer studies of patient survival time Equipment failure and failure time analysis […]

GETTING THE MIX RIGHT FOR BETTER PROFITABILITY

ACCORDING to the EIA’s most recent forecasts, global oil consumption will average 92.6 million bpd in 2020, down 8.1 million bpd from 2019. This decline comes from reduced travel and diminished industrial activities due to the COVID-19 pandemic. While the decline in consumption has been immediate, the production and distribution chains (extraction, separation, transportation, storage, blending and refining) unwind at a much slower pace. Decisions to cap wells are not taken lightly, because shuttering productive sites can result in a complete loss of unrecovered reserves once a well is capped. Today, almost 100 different countries produce oil, and for many, […]

RARECHEM’S INNOVATIVE DECK LIFTING SYSTEM USED AT DANGOTE REFINERY

THE 650,000 bpd Dangote Refinery, under construction in Lekki, Nigeria, will be the world’s largest single train refinery, when complete. It is large enough to provide Nigeria’s entire domestic need for refined products, as well as products for export. A big refinery needs a lot of tanks. At present, UAE-based firm ChemieTech of Sharjah is building 155 tanks at the site. Of these, 51 are floating roof tanks, 10 with a diameter of 92 m, eight with a diameter of 66 m, 25 with a diameter of 57 m and eight smaller tanks. Floating roof tanks present particular challenges, including […]

THE EVOLUTION OF TANK CLEANING

ROBOT implementation continues to increase globally and the rapid proliferation in robot capabilities – driven by innovations, means that they can do the jobs that are just plain dangerous for people. Not only can robots operate in hazardous environments where humans can’t, but they can also take on the tasks that pose a significant risk to human life. Over the last year Re-Gen Robotics has had the pleasure of working with some of the benchmark oil majors, who are embracing the company’s state-of-theart, explosion proof, Ex Zone 0 rated tank cleaning robots. These industry leaders are committed to enhancing safety […]

TWTG VALVE SENSORS OFFER RETROFIT SAFETY SOLUTIONS

THE INDUSTRIAL Internet of Things (IIoT) offers huge benefits to industry. With different parts of a facility connected centrally, data on temperature, pressure, inputs, outputs, flow and many more aspects can be gathered and monitored in real time, offering insights into plant performance, safety, and efficiency. This allows operators to make informed decisions on process improvements, maintenance, and safety, among other things, saving time and money, reducing incidents and improving the environmental sustainability and energy efficiency. Get enough data and it is possible to build a so-called digital twin of a facility, which can run virtually and offer even more […]

IDENTIFYING AND AVERTING FUTURE CATASTROPHIC VALVE FAILURES

HIGH quality industrial valve components are becoming an increasingly important driver in the push for maximum operational efficiency. Exposure to extreme conditions, both externally and internally, can result in catastrophic failures due to corrosion, erosion and cavitation, and remain a root cause of depleting valve performance and failures. For 13 years Provalve has provided specialist valve solutions within the petrochemical, refinery, oil and gas, power and general process industries. In 2017 Provalve became WSG Provalve, and as part of the Well Services Group is able to provide full lifecycle support to clients’ assets, and an integrated and managed service with […]

DEFINING THE VALUE OF DISRUPTIVE TECHNOLOGY

EARLIER this year Saudi Arabianbased Manifa Petroleum Services was one of the many technology service providers that were tasked with the challenge of partnering with Saudi Aramco to reduce the company’s US$200 million maintenance and turnaround budget by a minimum of 4% over the next two years through 2022. The company showed that by employing Oreco’s non-man entry closed loop tank cleaning systems, the company could not only help Saudi Aramco save money, but also improve safety and environmental practices and drastically reduce tank downtime. Manifa Petroleum Services invested in the Oreco non-man entry automatic tank cleaning (ATC) technology in […]