The experts at Scanjet explain how its new tank cleaning machine improves safety and efficiency on site

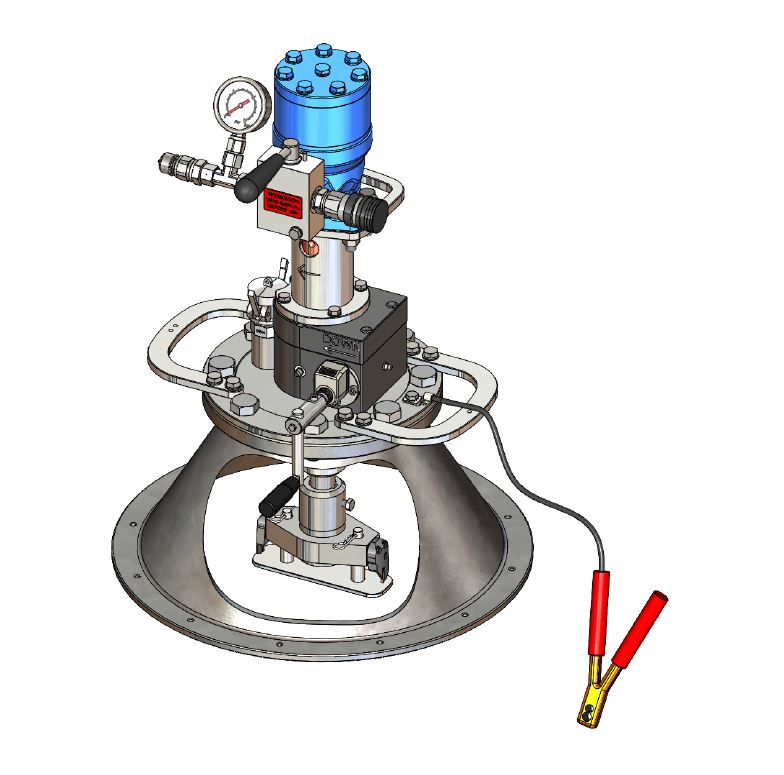

In the oil and gas and petrochemical industries, maintaining safety and efficiency is a constant challenge. The introduction of the Scanjet SC 60H Automated Tank Cleaning Machine marks a significant advancement in addressing these issues, especially for cleaning large crude oil storage tanks.

Avoiding Human Risk

Traditionally, tank cleaning has been a risky and labour-intensive process, often involving exposure to hazardous materials and environments. The SC 60H, introduces an innovative approach to this task, focusing on safety and efficiency. Its design and operation reflect a commitment to reducing the risks associated with tank cleaning. A standout feature of the SC 60H is its ATEX certification, demonstrating suitability for use in highly explosive environments. This certification is vital, ensuring compliance with stringent safety standards and enhancing overall process safety.

Cleaning Efficiency

A significant advantage of the Scanjet Automated Tank Cleaning Machine is its robust cleaning nozzle which is highly effective at breaking down and removing sludge. The machine utilises re liquified or recycled oil as the cleaning agent. This allows it to be able to manage solids, a crucial aspect of crude oil tank cleaning.

The SC 60H is designed with a compact, slim profile, allowing it to conveniently fit into the existing support leg structures of tanks. This design leads to a quick and straightforward installation process, reducing the time personnel needs to spend on the tank roof. For scenarios where current openings are unsuitable, the SC 235 ScanCutter, Scanjet’s ATEX-approved cutting tool, can be employed to create new access points.

Improving Safety

A crucial safety aspect of the SC 60H is its remote operation capability from outside hazardous zones. This feature significantly reduces the need for personnel to enter dangerous areas, aligning with industry trends of minimising no-man entry into high-risk hazard areas. The Scanjet SC 60H Automated Tank Cleaning Machine revolutionises oil tank cleaning with safety, efficient cleaning, and easy installation, promoting no-man entry for hazardous areas.

For more information: