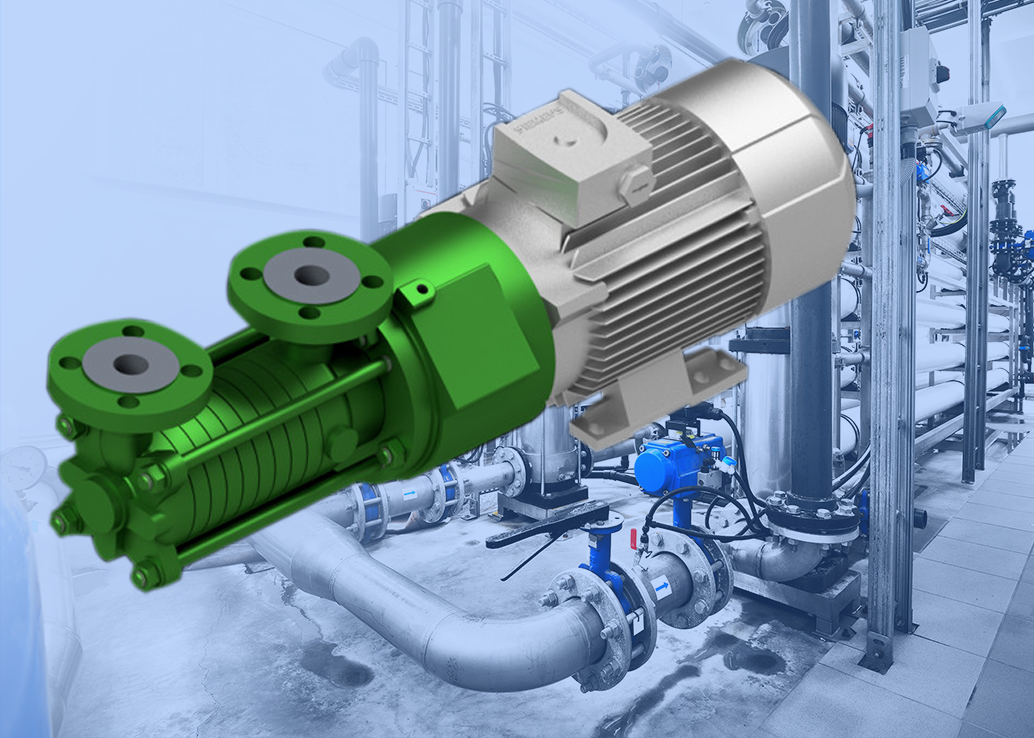

UK firm Michael Smith Engineers has launched a new series of pumps designed specifically for the safe and reliable pumping of thin, low-viscosity liquids such as liquefied gases or refrigerants.

The new Dickow WPM Series of self-priming, horizontal, side-channel pumps is suitable for handling clean liquids without solids in chemical and petrochemical industry applications. The pumps have a magnet drive single or multi-stage side channel design to pump thin liquids at four-pole speeds of high differential heads up to 150 m, covering flow rates from around 2 L/minute up to 40 L/minute. The pumps can also prime empty suction lines after initial filling. The maximum operating temperature is 150ºC. The

The magnet coupling with the static containment shell forms a hermetically sealed leak-free system, eliminating the need for double mechanical seals, along with external fluid reservoirs and associated control equipment. The single elements of the multipolar magnet coupling are made from neodymium-iron-boron, and the driven rotor magnets are encapsulated and not in contact with the pumped liquid for maximum lifetime operation.

The Dickow series pumps are available in 316 stainless steel or Hastelloy-C materials, and in two designs, one for pressures up to 16 bar, and the other for system pressures up to 110 bar. The company says that the pumps are more economical that standard centrifugal pumps when the combination of low capacities and high heads is required.