Learn how Kanon Loading Equipment is supporting the delivery of CNG in Egypt to help ensure a secure, continuous gas supply

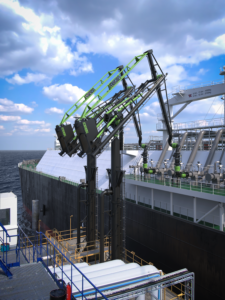

The successful delivery of six 16” high-pressure compressed natural gas (CNG) loading arms by Kanon Loading Equipment marks a significant milestone in Egypt’s energy sector. These loading arms, equipped with emergency release couplings (ERC) and hydraulic quick connect/disconnect (QC/DC), are essential for ensuring a continuous and reliable CNG supply into the country’s power grid. Without these arms, natural gas could not be efficiently transferred, leading to potential supply disruptions.

What makes this project particularly noteworthy is the exceptionally short delivery timeframe; completed more than five months faster than standard lead times. This was achieved through engineering precision, agile manufacturing, and Kanon’s close collaboration with industry partners.

The Requirements

Kanon Loading Equipment specialises in high-pressure fluid transfer solutions. The 16” high-pressure CNG arms designed for this project required:

• Pressure: 116 barg

• Maximum flow rate: 10,000 Nm³/h per arm

• Swivel joint load capacity: 150.92 tonnes-force per joint under maximum pressure conditions (tested for 225 barg, above project requirements)

• Temperature range: -45°C to +80°C

• Cycle life expectancy: 100,000 operational cycles before major maintenance

Unlike traditional loading arms engineered for 24-hour transfer cycles, these units must function as a permanent connection for at least nine months. This extended operational duty needed an optimised structural design, enhanced fatigue resistance, and rapid seal replacement capabilities to minimise downtime.

Speedy Turnaround

Delivering this project under such constraints required a fundamental shift in Kanon’s production strategy. Several key factors contributed to achieving this accelerated timeline:

- Strong supplier partnerships: Rather than relying on ad-hoc subcontractors, Kanon leveraged its long-standing relationships with highly specialised suppliers, ensuring seamless integration of critical components. Van Bilsen, a key machining partner responsible for the swivel joints, operated on a 24/7 production cycle, reducing lead times by 60%. Electromach, a trusted supplier of control systems, achieved a schedule improvement, reducing lead times by a remarkable five months through optimised internal workflows.

Advanced welding and fabrication techniques: High-pressure loading arms require precision welding, particularly for components exposed to continuous high-stress conditions. One of the major bottlenecks was the availability of certified welders capable of working under these strict tolerances. To mitigate this, Kanon implemented prefabricated sub-assemblies, reducing welding complexity in final assembly, as well as automated orbital welding processes for primary load-bearing components, which improve efficiency by 30% compared to manual welding.

Advanced welding and fabrication techniques: High-pressure loading arms require precision welding, particularly for components exposed to continuous high-stress conditions. One of the major bottlenecks was the availability of certified welders capable of working under these strict tolerances. To mitigate this, Kanon implemented prefabricated sub-assemblies, reducing welding complexity in final assembly, as well as automated orbital welding processes for primary load-bearing components, which improve efficiency by 30% compared to manual welding.- Real-time quality control: Traditional end-stage testing can slow down production significantly. To eliminate delays, Kanon Loading Equipment implemented inline testing throughout the production process. Hydrostatic pressure testing at 1.5 times design pressure (116 barg) ensured zero leakages under extreme conditions. Additionally, ultrasonic and radiographic weld inspection identified micro-defects before assembly, improving reliability. Swivel joint torque testing verified that operational forces remained within API RP 14E guidelines, ensuring smooth movement under pressure.

- Proactive supply chain and logistics strategy: Material availability often dictates project timelines. To erase potential delays, Kanon Loading Equipment implemented early procurement of critical components, reducing supply chain risks. In addition, just-in-time (JIT) logistics for non-critical materials, prevented overstocking delays, as well as strategic component positioning, allowing simultaneous fabrication across different facilities.

Performance and Operational Cost Efficiency

The CNG loading arms were designed with an emphasis on long-term cost efficiency and low total cost of ownership (TCO). Key advantages include optimised structural weight, which reduces dynamic stresses on critical components, and extended seal life that requires fewer maintenance interventions. The modular ERC design allows for field-replaceable components, and a proven mean time between failures (MTBF) of greater than 30,000 hours minimises downtime.

Following installation, these CNG arms will function as a permanent transfer solution for nine months, operating under high- pressure conditions while maintaining optimal performance. The project completion solidifies Kanon’s leadership in high-pressure loading tech, establishing new industry standards.