Sanjeev Verma explains how Biz4intellia’s smart tank level monitoring system can be used to gain actionable insights

Traditional or manual ways of monitoring storage tanks can lead to certain errors during the monitoring process, creating a challenging situation for the plant managers to measure the fluid quantities accurately. Above and below-ground installations require proper management and monitoring, allowing better decision-making regarding business and profits.

The Internet of Things (IoT) is now helping multiple industries flourish, and is increasingly being harnessed to improve tank storage facilities.

CHOOSING A SMART TANK LEVEL MONITORING SYSTEM

Several manual methods and tools can be used to measure the level of tanks. From visual inspections to floats and ultrasonic sensors, there has been a drastic uplift in the industry to accept smart level measuring techniques.

Traditional manual inspections and measuring sticks are one of the inexpensive methods of level measurement, but they are highly labour-intensive and errors are likely. Automated methods like floats and submersible pressure transducers significantly minimise the risk of errors and simplify processes for better outcomes.

Many industries that deal with fluid products have a rising demand for technical solutions to measure tank levels and fluid quality. IoT-powered solutions mainly use ultrasonic sensors for accurate tank level measurement. These sensors use sound waves, which are immune to colour, transparency, and reflective properties, and are unaffected by light conditions, allowing accurate measurement of the tank levels.

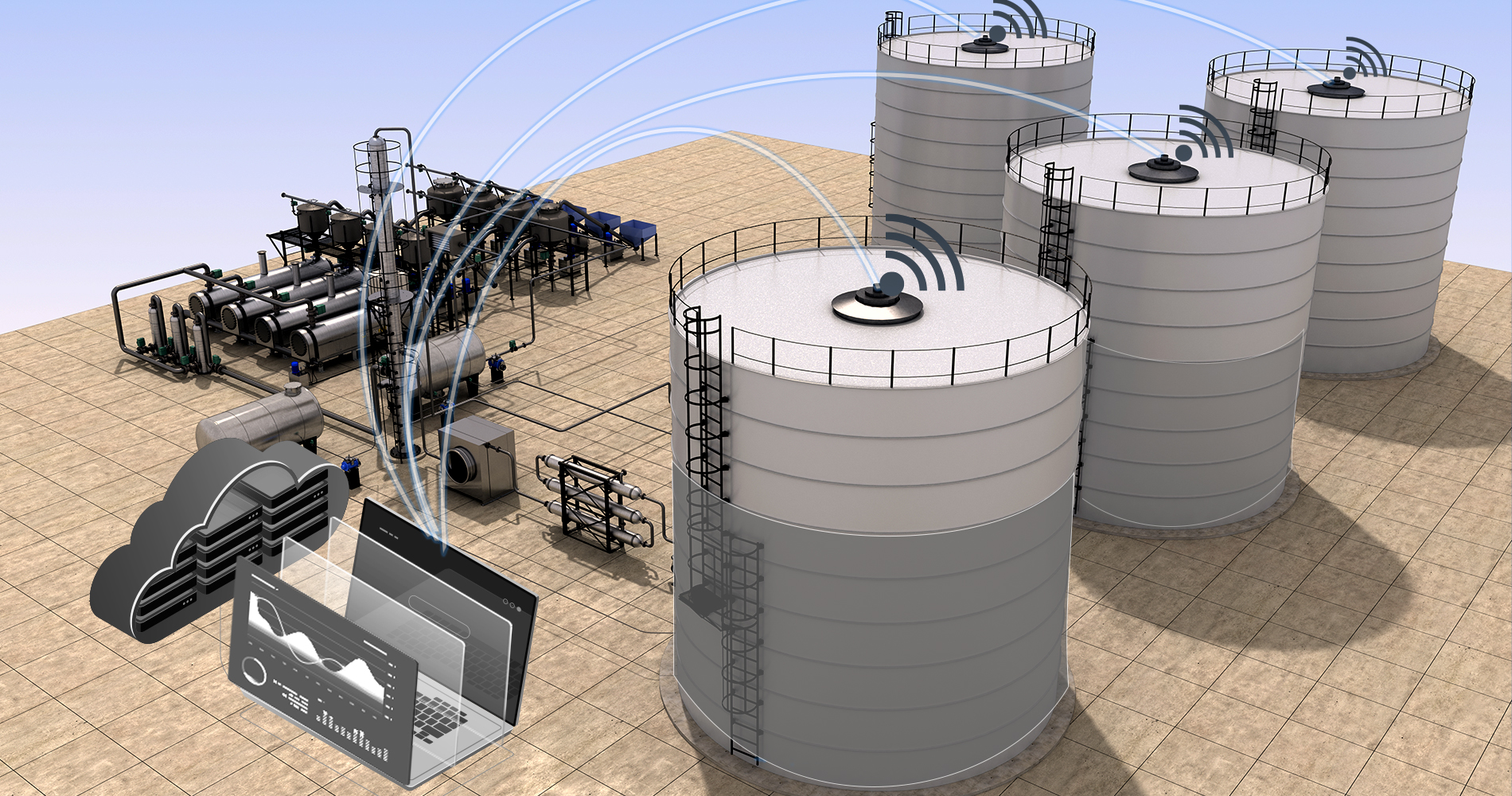

Using a wireless network is a cost-effective solution that provides real-time data and versatility to help businesses transform according to industrial changes. Integrating a smart tank level monitoring system that utilises ultrasonic sensors and a wireless network consists of many advantages, such as: –

- time and money savings;

- real-time monitoring and instant alerts; and

- adaptability with changing industrial needs

Connecting smart level measurement tools wirelessly is one of the most cost-effective methods, where infrastructural changes are minimal and it is easier to implement the smart solution. Also, the sensor connectivity enables plant managers to easily access the tank level data in real-time. To integrate smart tank level monitoring, one option is Biz4intellia’s IoT-powered solution.

BIZ4INTELLIA’S SMART TANK LEVEL MONITORING SYSTEM

The primary focus of developing a smart tank level monitoring system is to increase industrial productivity. Biz4intellia’s Smart Tank Level Monitoring System is a wireless solution that provides remote operability and is effectively compatible with both residential and commercial applications.

Biz4intellia’s tank level monitoring solution is equipped with advanced analytics that enables predictive maintenance for different types of tanks installed in any location. It has multi-channel alerting features that help identify every increase or decrease in the tank levels, and obtains the liquid utilisation pattern that eliminates any fluid wastage due to leakages. It allows the terminal to keep a real-time check on the stock availability and successfully manage the supply chain process.

The solution is embedded with multiple wireless ultrasonic sensor devices that are easily compatible with LoRaWAN gateway connectivity. These devices are suitable to use with different kinds of liquid products, such as anticorrosive liquids, fuel, acid, wastewater, and volatile liquids. Biz4intellia uses high-tech components that work by transmitting ultrasonic waves to the liquid’s surface and detect the depth of the tank through advanced mathematical calculations. This way you get an accurate measurement of the liquid’s level and volume data.

CASE STUDY

Biz4intellia executed the tank level monitoring solution and its services for a major citrus juice producer. It used the system to mitigate the product stockage issues and boosted productivity at significant levels. Initially, the company faced many challenges, such as calculating the volume of irregularly shaped tanks, different hardware checks on the tanks for testing, signal transmission through heightened tanks, and capturing data from multiple tanks of different kinds.

Using Biz4intellia’s tank level monitoring solution, it became easier to keep a strict eye on the levels and volume readings of the juice stored in the tanks. Biz4intellia delivered end-to-end services, allowing staff to observe the juice levels in the 45’ (13.7 m) storage tanks/tankers in real-time. It further helped them observe instant volume readings of the juice stored in the tankers from remote locations. These tanks were located in extremely cold areas where temperature recordings had been in minus degrees. But with the help of Biz4intellia’s advanced in-built calculative features, it was easier for the client to deploy and execute the system.

The data obtained from the juice tanks is stored in a cloud server, which is then displayed on the mobile and web-powered dashboards of the user. It helped the client to know the exact location of every device installed on the site, obtain real-time readings of juice level in the tanks, set threshold levels to gain instant alerts, use advanced analytics to analyse and process data, create a simplified management process for seamless process execution, and much more.

The solution keeps all possible business requirements in mind. It is applicable for both fixed and movable tankers. It is highly flexible and can also be extended to measure the volume of the liquid as per the requirement.

A smart tank level monitoring solution is a suitable fit for: –

- Fuel – IoT-powered solutions play major roles to curb unnecessary fuel usage and provides actionable insights for the managers to make better decisions. Also, it becomes easier for the managers to focus on multiple parameters like overflows, shortage of fuel supply, leakage areas, etc. With the incorporation of advanced sensors and gateways, the smart tank level monitoring solution automatically monitors fuel levels inside the tank, ensuring adequate stock levels at all times and detecting potential leaks to reduce any fuel wastage.

- Beverages – A smart tank level monitoring solution is highly compatible with all kinds of tanks, including small storage tanks. It is possible to identify the presence of contaminants and get real-time updates on the same by integrating an IoT-powered system to measure beverage levels. It also ensures the availability of the beverage stock by calculating the exact amount of production for sufficient supplies.

A smart tank level monitoring solution enables a smarter approach to maintaining tank stocks, boost product sales and ensure quality.

For more information:

Sanjeev Verma is the founder and CEO of Biz4Group, based out of Orlando, FL. He has 20+ years of experience in boosting IT-based startups to success. In the past, he has worked on leadership positions with Marriott Vacations, Disney, MasterCard, State Farm, and Oracle. The company headed by him excels in developing, implementing, and monitoring digital solutions ranging from IoT solutions and products, mobile and web development, and digital marketing to full stack development and CMS solutions.

www.biz4intellia.com