THE BEST STOCEXPO YET!

Find out what happened at the industry’s leading trade event: StocExpo. On 14-16 March in Rotterdam, the Tank Storage Magazine team, along with organiser Easyfairs, held the StocExpo conference and exhibition. The leading event brought together a whole host of terminal professionals and industry experts looking to connect with each other and share exciting new innovations. A year of firsts With fresh branding to represent the energy transition and future fuels, this year’s StocExpo kicked off with a terminal tour of Koole Terminals’ leading Tankstorage Botlek facility in the Port of Rotterdam. Led by a representative from the port, a […]

PREVENTING FALLS AND PROTECTING WORKERS

![[12:38] Cyann Fielding Carbis Loadtec Containerised Metering Skid with Vertically Elevating Platform and Arms 1](https://tankstorage.com/wp-content/uploads/2023/04/MicrosoftTeams-image-scaled-1-1024x827.jpg)

Cyann Fielding speaks to industry experts to gain the best advice for your terminal’s fall prevention and protection measures. In tank storage operations, working conditions often involve heights, bringing risks for manual workers. The risk of falls is common in the process of unloading trucks, working on tank roofs, or accessing higher areas. So, operators need to be aware of these risks and know how to mitigate them. For terminals, maintaining an environment with the least possible threat of an incident occurring is imperative for safe and efficient operations. Fall prevention measures allow operators to implement solutions to protect their […]

INNOVATIVE CONSTRUCTION FOR MAMMOTH PROJECTS

Bora Aydin at Walter Tosto delves into a recent project for the design, fabrication, construction and supply of bullet tanks for the biggest LPG storage plant in Italy. bullet tanks are both aboveground and underground (mounded) cylindrical vessels, which are considered to be one of the storage options to hold liquids or gases at pressure values different from the atmospheric pressure. They provide an ideal solution for supporting high capacities of bulk storage with efficient project delivery, lower risk of failure, easy maintenance and operation. Based on the application and the geographical conditions, bullet tanks can be installed both verically […]

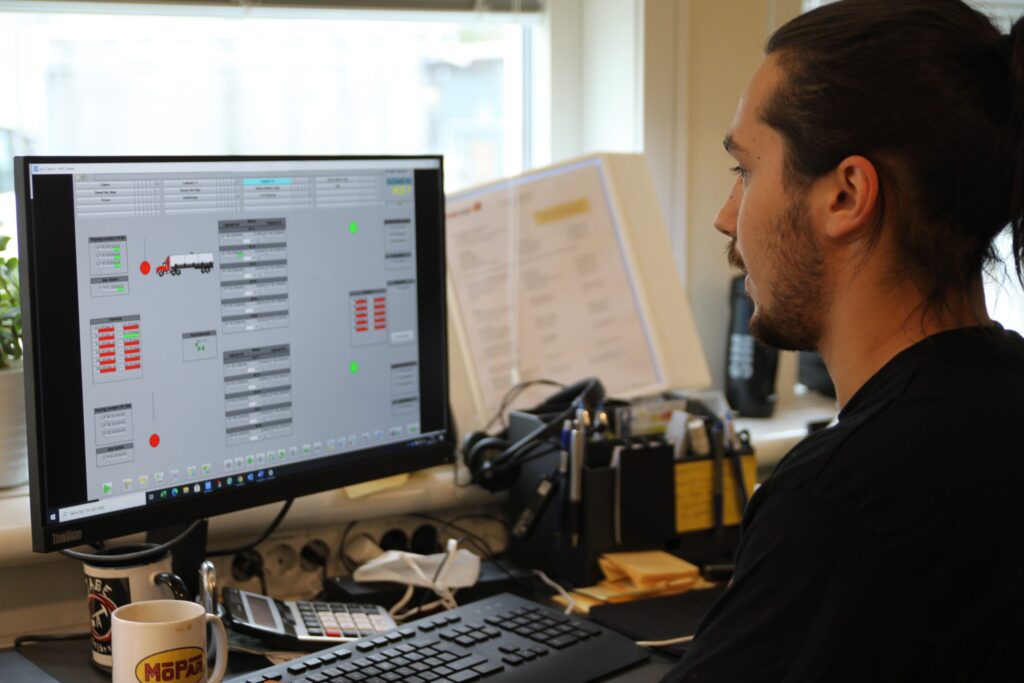

INCORPORATING AUTOMATIC DEPOT MANAGEMENT

Discover how OKQ8 works with PlantVision to increase reliability, with a future-proof system using Siemens’ software and products. When OKQ8 needed to streamline depot management at its oil port in Sundsvall, Sweden, the company selected the Siemens solution partner, PlantVision, to modernise and fully automate the fuel loading and unloading process. Using Siemens’ innovative Digital Enterprise portfolio has resulted in a future-proof and significantly more efficient fuel management solution. ‘We want to get away from the ‘we’ve always done it this way’ mindset,’ says Marcus Lundmark, project manager at PlantVision, who focuses on helping customers prepare for the future. ‘We […]

LOADING ARM OPERATIONAL PRODUCTIVITY AND ADVANCED SAFETY

Tank Storage Magazine explores the future of loading arms with improved safety, operations and efficiency. Loading arms facilitate the transfer of liquid or liquified gas, from one tank to another through an articulated pipe system. This usually consists of rigid piping and swivel joints. Loading arms unfold to get the required working envelope to load or unload the tanker, and the reverse to retract or get a minimal space for parking or storage. With increasing demand for digitalisation across the sector, loading arm suppliers are being expected to implement safer and more efficient products. So, Tank Storage Magazine consulted the […]

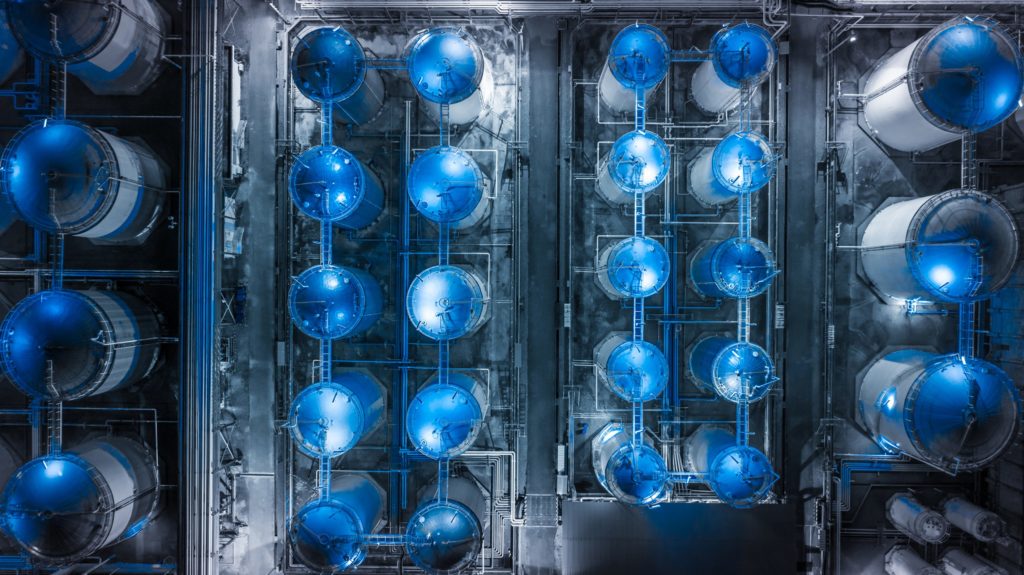

NOBODY WANTS TO THINK ABOUT WASTEWATER

The experts at Aquacycl explain new sustainable wastewater treatment options to achieve permit compliance at tank terminals. Wastewater generated from operations at bulk storage terminals can include process wastewater, secondary containment wastewater and stormwater management. Dealing with these wastewater streams are usually not considered core to the business, but it needs to be carefully managed to avoid unpermitted discharges of harmful chemicals and petrochemicals to the environment. Permit violations can result in large fines, negative publicity and, ultimately, potential disruption to operations. One of the main sources of process wastewater is from cleaning operations, washing out tanks to facilitate changeovers […]

FASTER, SMARTER, SAFER: NO-MAN ENTRY TANK CLEANING SOLUTIONS

Re-Gen Robotics’ no-man entry tank cleaning service provides huge logistics, cost and risk benefits for tank owners. Tank cleaning is required at oil terminals as part of their ongoing maintenance programmes, generally every three to five years, or to undertake specialist tasks, such as changing product in the tank, decommissioning, assessing contamination, structural defects, and corrosion. SLUDGE AND SEDIMENT Sludge and sediment removal is a necessary operation that operators of oil storage facilities, refineries and processing plants manage as part of their facilities’ maintenance procedures. Sludge and sediment can mount up in oil storage tanks in various ways. When the […]

WHY USE HUMANS WHEN WE HAVE ROBOTS?

Molly Cooper explores no-man entry tank cleaning robots and why there is no longer a need for humans to do the job. No-man entry tank cleaning in the sector has grown over recent years. Companies have an obligation to protect their staff and keep them out of harm’s way. Entering tanks is not an easy task and requires qualified, registered personnel. ‘Thinking about what is considered the worst kind of manual labours, in terms of working environment and type of manual activity, tank cleaning definitely fits the description,’ says Daniel Devò, export sales manager at Gerotto. According to a 2021 […]

FIRE SAFETY UPDATES

A collection of experts share their insights into the latest in fire safety, including fluorine-free foams, strategies and the right equipment PHASING IN FLUORINE-FREE FOAMS Hans Huizinga, extinguishing foam consultant, Kenbri Fire Fighting Back in 2021, the big industrial users of the foam were complaining about the cost of a fluorine free foam. Now, this excuse isn’t working and instead of a choice – it is a must. Change in opinion Public opinion is evolving. In the Netherlands, the government has gotten involved with the discussions on foam. Environmentalists are asking questions to the Ministry of Public Health and […]

THE SAFE, SUSTAINABLE AND FLEXIBLE CARRIER FOR THE ENERGY OF THE FUTURE

Rail transport will be essential to transport LNG across the globe, says VTG. In April 2021, the European Parliament and the Council of the European Union agreed on a new European climate law and substantially raised the EU’s greenhouse gas reduction target for 2030. At the same time, greenhouse gas neutrality by 2050 – which is at the heart of the Green Deal – was for the first time anchored in law at the EU level. Energy-intensive industries and the mobility sector in particular face huge challenges as a result. Transitioning from processes previously based on fossil fuels demands innovative […]

THE GLOBAL IMPACT OF TANK STORAGE

FETSA teams up with the Hague Centre for Strategic Studies to manage geopolitical challenges facing the storage sector. Recent geopolitical changes have led to, and are leading to, fundamental changes in the global energy system, energy policy and trade. These include decoupling between ‘the West’ / G7 economies and Russia, as well as decoupling of critical supply chains between this bloc and China. These trends have been elaborated in strategic documents issued by the USA, G7, NATO, the European Union and to a lesser extent the G20. Energy security has become a priority. The energy transition has been accelerated through […]

A MODERN WOMAN IN A MODERN WORKFORCE

Gizil GmbH CEO, Esma Gulten, shares her story of perseverance and entrepreneurship in a male-dominated industry. Established in 2012, Gizil is a full-service engineering, procurement, and construction provider for the tank terminal industry that focuses on the digitalisation of facilities. CEO Esma Gulten founded the company with her partner, having worked in the tank terminal industry for some time previously. ‘I graduated technical university as an industrial and mechanical engineer with a double major,’ says Gulten, who began her career with Siemens – one of the giants in energy industry. ‘Although I had no idea about oil and gas industry […]

CUSTOMER IMPORTANCE & OPERATIONAL EXCELLENCE

MEMBERSHIP FAQs Already a member, or planning to become one? Here you can find answers to our frequently asked questions! You can find a list of our frequently asked questions. If you have further questions, our TSM team will be happy to help. How do I become a TSM member? Starting TSM membership is easy! Sign-up to become a member by clicking the ‘Become a Member’ icon. What do I get as a part of the membership? Your TSM membership will keep you up-to-date with the latest news and insights, research, weekly newsletter and many more.You will be a part […]

BRINGING LNG TO GERMANY

MEMBERSHIP FAQs Already a member, or planning to become one? Here you can find answers to our frequently asked questions! You can find a list of our frequently asked questions. If you have further questions, our TSM team will be happy to help. How do I become a TSM member? Starting TSM membership is easy! Sign-up to become a member by clicking the ‘Become a Member’ icon. What do I get as a part of the membership? Your TSM membership will keep you up-to-date with the latest news and insights, research, weekly newsletter and many more.You will be a part […]

SAFETY, SAFETY, SAFETY

Molly Cooper Journalist at Tank Storage Magazine. Features SAFETY, SAFETY, SAFETY By Molly Cooper February 22, 2023 Co-founder of Terra Inspectioneering, Marien van den Hoek, discusses winning gold and the future of their technology. At the 2022 Tank Storage Awards, gold was presented to Terra Inspectioneering in the Safety Technology category for the Terra UT drone. The judges said the technology was chosen due to its ability to drastically reduce the amount of time needed for both working at height and confined space entry; automating tasks and reducing employee risks. When asked how it felt to win the award, co-founder

INNOVATION AND ENVIRONMENTAL IMPACT

Molly Cooper Journalist at Tank Storage Magazine. Features INNOVATION AND ENVIRONMENTAL IMPACT By Molly Cooper February 22, 2023 Director of Rubis Terminal Rotterdam, Luc Jorissen, tells Tank Storage Magazine about winning gold and their focus on the environment. The winner of the Terminal Innovation category is the terminal that dares to try new technologies and implements the best practices to ensure efficient operations and the best customer service. Rubis Terminal Rotterdam (the Netherlands) was chosen by the Tank Storage Awards’ panel of impartial judges to win gold at the 2022 ceremony for being a pioneer in using the latest technology

ACHIEVING OPERATIONAL EXCELLENCE, THE A3D WAY

Anamika Talwaria Editor for Tank Storage Magazine & Chair of Women in Tanks Features ACHIEVING OPERATIONAL EXCELLENCE, THE A3D WAY By Anamika Talwaria February 22, 2023 A3D’s commercial director Colin Pittman explains how a digital solution can help you manage risks to your terminal. Your terminal assets are instrumental to the success of your business. With A3D’s digital solutions, you have the flexibility to view and manage the health of your terminal with confidence – to achieve operational, safety and regulatory compliance and to manage market volatility, environmental, financial and employee risks to achieve your productivity goals. With accurate data

ADJUSTING TO PFAS BANS

The experts at Saval share the company’s innovative solutions for firefighting foams compliant with the latest standards. In the tank terminal industry, firefighting foam is the product of choice for fighting fire and spill scenarios. Usually this involves an automatic system that is ready to operate whenever an incident occurs that causes a tank bund area spill or tank fire. Over the years, foam producers have been developing multi-purpose foam concentrates that can be used for many hydrocarbons, alcohols and other liquids. These foam types contain fluoropolymers (PFAS) that improved the foam’s performance in extinguishing fires, but these are also

ELECTRIC RTO: AN EFFICIENT SOLUTION TO ELIMINATE VENTING EMISSIONS

José Miguel González, engineering director at Tecam, explores the challenges and solutions of venting emissions. In a world like today’s, with crisis, wars and materials stock shortages, it becomes crucial to define more conservative storage policies, while also implementing a higher level of environmental protection. Especially at tank terminals, it is essential to have correct, safe exhaust air management to eliminate volatile organic compound (VOC) emissions generated during gas venting. These emissions usually happen during daily operations at tank terminals, such as filling and emptying tanks, connecting and disconnecting units, breathing, cleaning, draining, purging, etc. Recently there has been a

VAPOUR RECOVERY AND ELIMINATING EMISSIONS

Molly Cooper explores how the right vapour recovery systems can aid in the global target to reduce emissions. VAPOUR RECOVERY is the process of collecting the vapours of products and fuels so that they do not escape into the atmosphere, where they can potentially cause harm. José Miguel González, engineering director at Tecam explains: ‘The hydrocarbons that are released contain volatile organic compounds (VOCs) that evaporate easily. In addition to representing a significant loss of product and therefore sales, evaporated vapours have serious effects on human health and are harmful to the environment.’ REDUCING VOCS In response to the pressures

MAINTAINING QUALITY; INCREASING SUSTAINABILITY

Jon Loach, managing director at Dantec, explains what the company’s recent overhaul means for its customers and the industry. Since starting out as a gasket cutting business in 1969, Dantec has become a world leader in composite hose technology. Increased market demand for reliable composite hoses caused Dantec to begin manufacturing, working towards a commitment to innovation, minimising environmental damage, and above all else, safety and efficiency. SUSTAINABLE BUSINESS MINDSET Although sustainability is trending as a buzzword in just about every industry, putting the focus of environmental responsibility at the forefront of business is more than greenwashing. Working with its

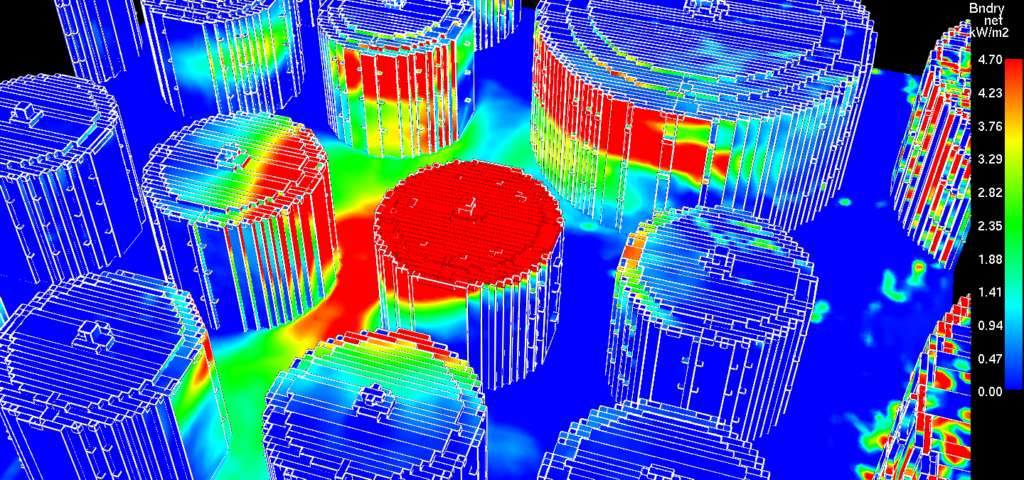

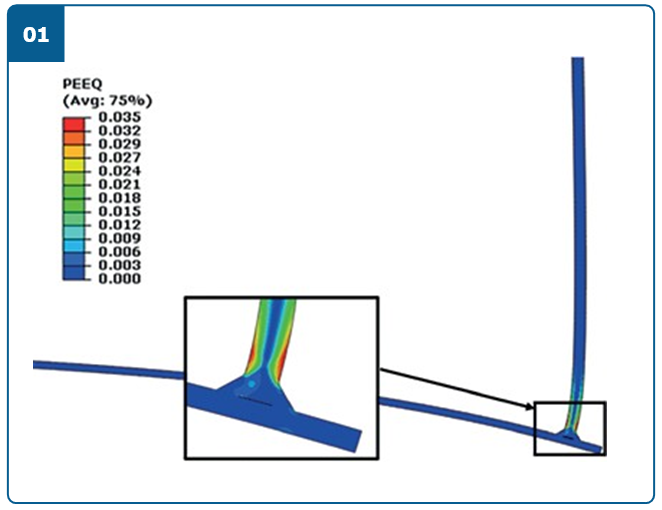

AST FITNESS-FOR-SERVICE

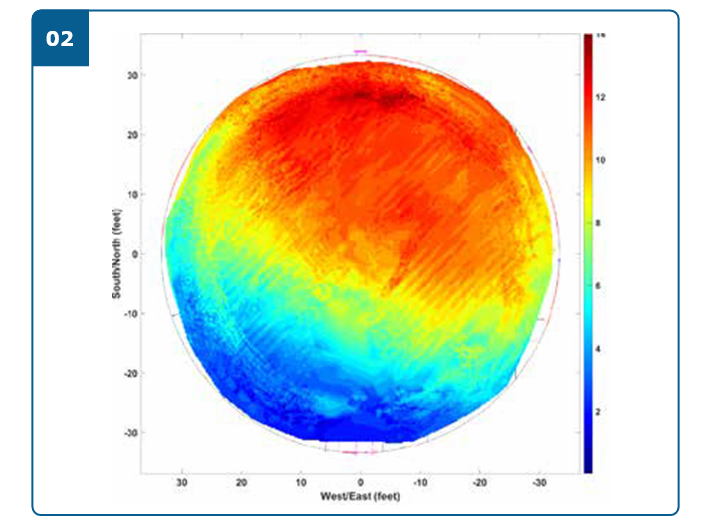

The experts at Equity Engineering Group discuss the application of API 579-1/ ASME FFS-1 Fitness-for-Service to aboveground storage tanks. API 579-1/ASME FFS-1 Fitness-For-Service (API 579) is the go-to standard for assessment of fitness- for-service (FFS) of fixed equipment. Aboveground storage tanks (ASTs) designed to API 650 Welded Tanks for Oil Storage and API 620 Design and Construction of Large, Welded, Low- Pressure Storage Tanks are specifically included in the scope of API 579. The assessment procedures in API 579 may also be applied to pressure- containing equipment constructed to other recognised codes and standards, including international and internal corporate standards.

ROBOTICS AND RISK BASED INSPECTION ASSESSMENTS

Anamika Talwaria Editor for Tank Storage Magazine & Chair of Women in Tanks Features ROBOTICS AND RISK BASED INSPECTION ASSESSMENTS By Anamika Talwaria February 21, 2023 Rafael Rengifo, midstream director at Becht, looks at the industry trends in tank integrity and the latest in robotic technology and RBI assessment approaches. Aboveground storage tank (AST) owners and operators are under pressure to improve risk adjusted economic return through proactive and thorough Environmental, Social, and Governance (ESG) policies. Quality programmes that include tank inspection, repair, and maintenance have historically been developed using a time-based inspection approach to comply with API 653 or

A COST-EFFICIENT TANK GAUGING SOLUTION

Tomas Hasselgren, global business development manager for tank gauging at Emerson, explains how emulation technology helps organisations replace old or malfunctioning equipment for safer operations. Many of the world’s bulk liquid storage tanks have been in service for a long time and rely on ageing tank gauging systems to support both overfill prevention and inventory management. Many systems are based on level measurement devices using servo technology. Although widely used, these devices have numerous drawbacks, including a poor reliability record and the need for regular maintenance. Servo gauges are mechanical devices with many moving parts, suffering constant wear and tear.

EMISSION-FREE, FIREPROOF GRP FLOATING ROOFS

Discover how German innovation from EPT has established fireproof GRP floating roofs for the tank terminal industry. Climate protection is a big task that requires many small steps. Renewal, innovation, and willingness to carve new ways. Germany is an industrial country and still lives on its value-creating industry. This sector of the economy, regardless of whether it is a refinery, chemical company or other plant, only functions if the supply of raw materials is secured. Storage tanks are currently used for this purpose and will continue to be needed in the future. The best form of environmentally friendly product storage

FASTER, SMARTER, SAFER: NO-MAN ENTRY TANK CLEANING SOLUTIONS

Regularly assessing tanks is imperative to maintain terminal safety and is driving demand for robotic cleaning solutions says Aidan Doherty, MD of Re-Gen Robotics. Failures and incidents at oil terminals can have extensive consequences for the environment and human health. When considering the cost of repairs, closure, remediation, claims and loss of share value, it can lead to a much higher impact for an oil terminal facility. It is easier for the companies involved to invest and ensure a proper level of safety to prevent adverse incidents from happening. ASSET INTEGRITY Asset integrity is a key element in maintaining process

REUSING LNG STORAGE TANKS FOR FUTURE FUELS

The experts at Linde Engineering explore the challenges of transforming LNG tanks for use with ammonia for hydrogen. At the time of writing, the world order of the past three decades appears to be on the verge of a radical change. Particularly in Europe, the search is on for political and technological ideas and solutions to minimise dependence on fossil fuels and thus reduce greenhouse gas emissions. LNG is considered a bridging technology due to its comparably clean combustion and the reduced amount of greenhouse gas emissions compared to other fossil fuels. The German government has published a new law

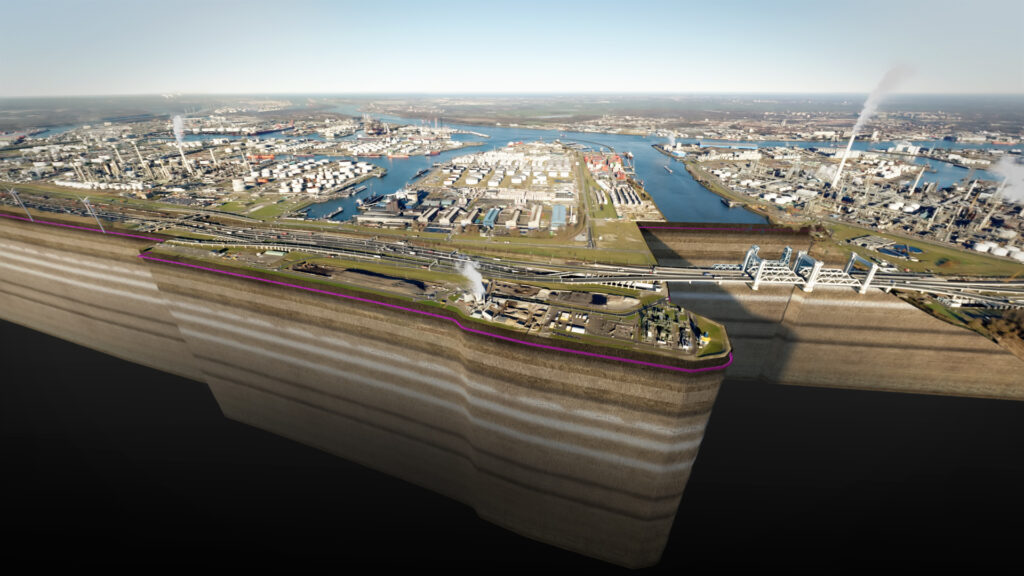

CARBON STORAGE UNDER THE NORTH SEA

Porthos plans to transport carbon and store it in empty gas fields under the Dutch North Sea, explains Nico de Meester, external relations manager at Porthos. The Netherlands has clear climate objectives: the emission of greenhouse gases must be reduced by at least 55% in 2030 compared with 1990. In 2050, the Netherlands aims to be climate neutral. One way to achieve these climate objectives is to capture and store CO2 (Carbon Capture and Storage, CCS in short). The Dutch Climate Agreement underlines the importance of CCS in the energy transition. CAPTURING CARBON The CO2 that will be transported and

RUSSIA, THE ENERGY TRANSITION & THE MARKET

Channoil Energy’s director, Mark Waddington, looks at how global events are set to impact the energy market in 2023. Major events have always shaped global energy markets, no less so than in the last three years. We have gone from a pandemic-led downturn to a sharp economic recovery, then to a war in Europe. 2023 is likely to be shaped by the return of China’s economy from strict lockdowns and the gradual recovery of other regions. There will also continue to be trade-offs between security of supply and driving the energy transition. RUSSIA TURBULENCE Russia’s invasion of Ukraine in February

18 YEARS ON: HAVE THE LESSONS OF BUNCEFIELD BEEN FORGOTTEN?

As the industry progresses, we must keep in mind the lessons from Buncefield, says Peter Savage, HSEC lead for HG Storage International. 2023 marks 18 years since the Buncefield explosion. This period effectively marks a whole generation away from the biggest explosion and fire in the UK since World War II. This is a potential generation where adults working in the industry won’t have lived through this incident, seen the television footage, the media coverage, or the devastation on the ground. Safety and operations professionals that followed the investigation and received the UK Health and Safety Executive’s reports will have

READYING THE TANK STORAGE SECTOR FOR HYDROGEN

FETSA’s executive director Ravi Bhatiani looks at hydrogen’s role in the energy transition and how the industry can adapt. The latest research carried out for FETSA by the Hague Centre for Strategic Studies showed that the large- scale adoption of hydrogen in the mid-term has many uncertainties. These include the demand, use cases, transportation means, and the carrier used to transport the product across long distances. The precise energy carriers that will be needed to transport and store clean hydrogen are particularly important to enable a hydrogen logistics chain to develop. FETSA expects that many carrier technologies will be used,

CREATING A BETTER FUTURE

Argent Energy’s head of supply chain, Victoria Oppenheim, tells Tank Storage Magazine about her experience as a working mother in the industry. Victoria Oppenheim was seven months pregnant when she embarked on her journey with biodiesel producer, Argent Energy. Oppenheim was headhunted from a role in the food industry to work in renewable energy. ‘I had no intentions of leaving the company I worked for but then I got a new and very bad manager, so when a headhunter called about the position at Argent, I started the process,’ she says. ‘Argent knew that I would only be operational for one