Steam Traps, common yet essential components in the process industry, are too often prone to failure, leading to wasted energy and increased costs. To prevent these issues, steam traps must be monitored regularly to detect and address malfunctions. Traditional steam trap monitoring methods involve manual inspection and testing, which can be time-consuming, labour-intensive, and, unfortunately, prone to human error.

This use case, built on TWTG’s industrial experiences with Steam Trap Monitoring, considers the challenges of traditional monitoring methods, and analyses how recent technological advancements have opened up the possibility of achieving a complete digital monitoring overview.

To demonstrate these technological advances, the team explores how using LoRaWAN technology can help industrial facilities improve efficiency while simultaneously reducing costs and enhancing safety.

The Challenge

Steam trap degradation and failure are still unfortunately common occurrences in the process industry. A good monitoring solution can help considerably reduce the risk of failure. However, traditionally, with potentially hundreds, if not thousands of steam traps within a busy facility, the cost of a complete solution was in the past, simply unfeasible.

Today, things are different – technological advances and reducing costs now bring effective total monitoring within budget. What is Revolutionising Steam Trap Monitoring is LoRaWAN Temperature-Based Detection. Steam trap degradation can now be effectively monitored through the simple addition of wireless NEON Temperature Transmitters.

The Solution

A pair of NEON wireless Temperature Transmitters create an ingenious monitoring solution for steam traps. These can identify anomalies and quickly react to potential issues, thus reducing energy waste whilst extending the lifespan of the equipment.

A LoRaWAN network requires minimal infrastructure and can be easily integrated into existing systems. The retrofittable sensor solution fits nicely with the LoRaWAN backhaul. Easily deployable in an active environment, sensors can be installed without any wireless path planning or complex wiring. For the engineer, it’s simple – just mount and forget. The system will activate a LoRaWAN sensor over the air, and the data will start coming in.

Measurement – How It’s Done

With two PT100 temperature probes attached to a single TWTG Temperature Transmitter, you can effectively detect steam trap failures in almost any industrial application.

This is achieved by installing the probes upstream and downstream of the steam trap and simply measuring the temperature difference between them. The solution uses temperature data to identify two types of steam trap failures: blocked traps and failed open traps.

When a steam trap is blocked, it prevents steam from flowing through the trap, causing the downstream temperature to decrease. By comparing the temperature difference across the trap to a pre-set threshold, an alert indicating a blocked trap is sent should the temperature difference fall below this point.

Alternatively, when a steam trap leaks, it allows steam to pass through even when it is not needed, causing the downstream temperature to increase. Again, an alert is sent by comparing the temperature difference across the trap to a pre-set threshold – should the temperature exceed this point.

Products used

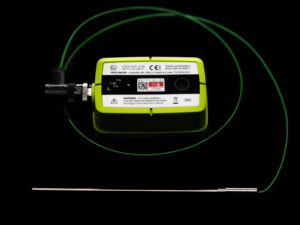

1 x NEON Temperature Transmitter (see datasheet here)

2 x PT100 temperature probes

Key Benefits

The NEON Temperature Transmitter effectively reduces energy waste and lowers energy costs by continuously monitoring steam traps and quickly detecting faults. An estimated 20-30% of steam traps fail annually, so an effective solution can contribute to significant cost savings across any facility.

In addition to the energy savings, an overall reduction in steam trap failure will have dramatic effects in improving safety, reducing maintenance costs and decreasing greenhouse gas emissions. Depending on the number of steam traps employed, an effective steam trap monitoring solution could conservatively lead to energy savings of up to 20% of a facility’s annual energy bill.

Conclusions

TWTG has examined the benefits of steam trap monitoring to detect and prevent costly steam fault traps, considered the challenges of traditional monitoring methods, and analysed how recent technological advancements have opened up the possibility of achieving a complete monitoring overview.

This use case lays out how to effectively monitor steam trap degradation through the simple addition of a wireless NEON Temperature Transmitter and two PT100 probes. Depending on the number of steam traps employed, such a monitoring solution could conservatively lead to energy savings of up to 20% of a facility’s annual energy bill, while improving safety, reducing maintenance costs and decreasing gas emissions.

TWTG’s NEON range of LoRaWAN sensors offer continuous monitoring, are fully wireless, have almost a decade of battery life, and are simply retrofitted to existing equipment. A combination of devices can be utilised to address the most common use-cases. Alternatively, for industrious engineers, sensors can be innovatively deployed to produce unique, tailored insight for particular scenarios.

About TWTG

TWTG is I-IoT. TWTG is the market leader in Industrialised (IECEx / ATEX) LoRaWAN sensors. Launched in 2012, the company has become known for its green NEON LoRaWAN products that solve industrial use cases. These wireless, battery-powered sensors revolutionise how industrial sites implement their digitalisation strategy.

Based in Rotterdam, the Netherlands (HQ) and Houston, US – As specialists in building IECEx / ATEX certified solutions for complex markets such as the oil and gas, petrochemical and utility sectors, TWTG’s devices contribute to greater accountability and environmental responsibility, while making facilities safer and increasingly efficient.

Keen to know more about this use case and the products involved? Please contact one of TWTG’s specialists.